J.G. Finneran Associates 250uL Glass Big Mouth Insert 4025BS-629. J.G. Finneran Associates authorized distributor . ☎ (800) 970-3646 Mon-Fri 8.00-17.00 ET or order online 24/7 J.G. Finneran Associates, 4025BS-629 – 250uL Glass Big Mouth Insert Volume: 250 uL, Vial Type: with Bottom Spring | Lab Equipment Depot Send Inquiry Chat Now Vials | VWR

2018/03/11 · when we design the locating feet for mold inserts, we have to consider if the inserts are easy to make, in general, the feet can be designed to 5×2.0mm or 4x3mm. Moreover, the feet should be placed on the short side for better manufacturing The feet need to be 0.5 -2.0mm shorter, better for making radius.

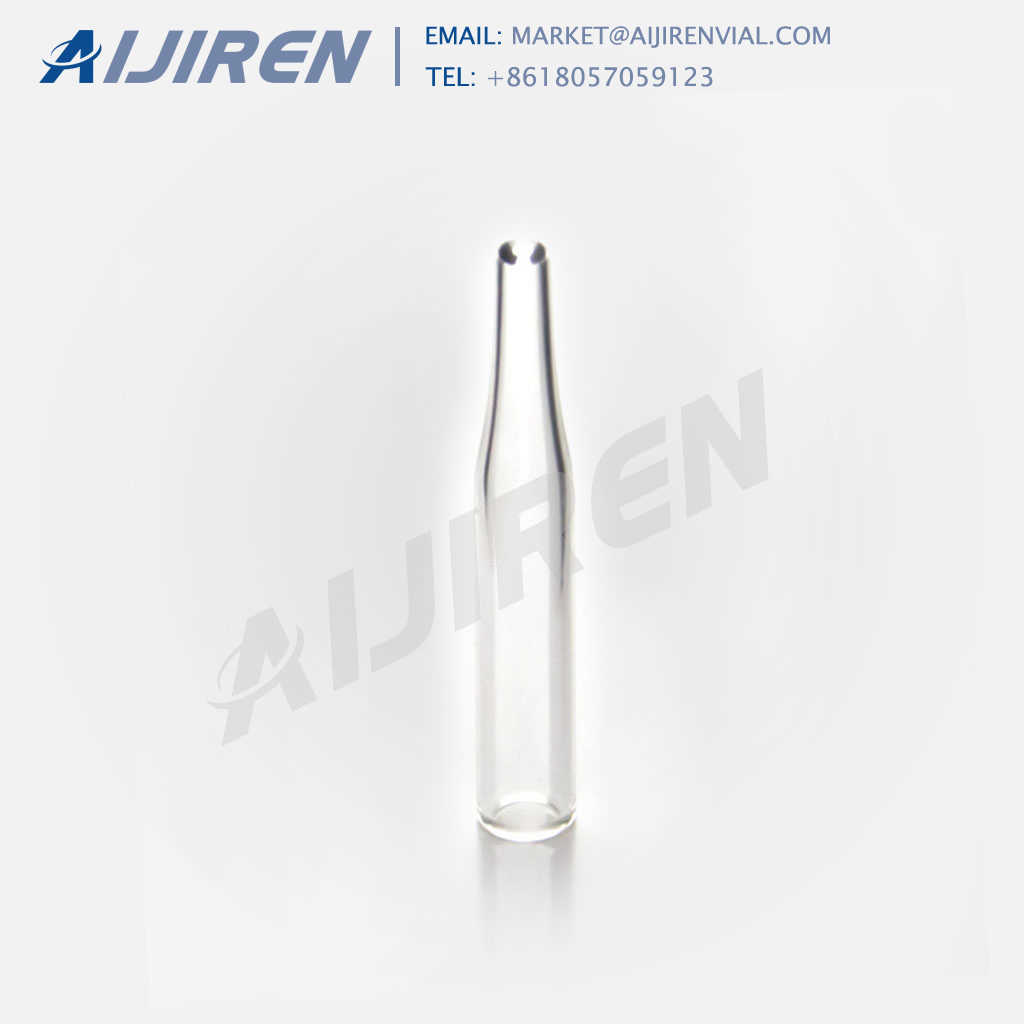

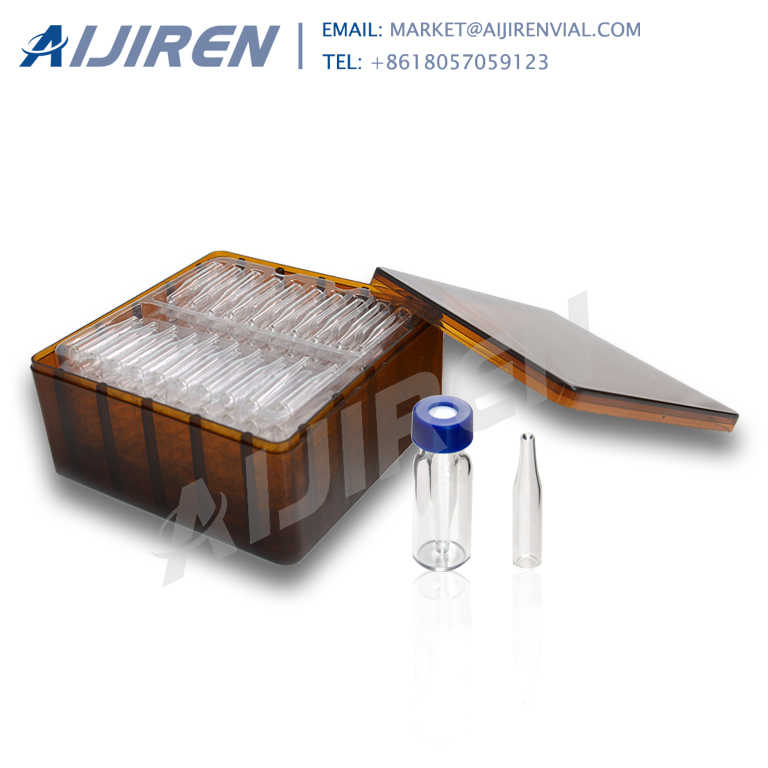

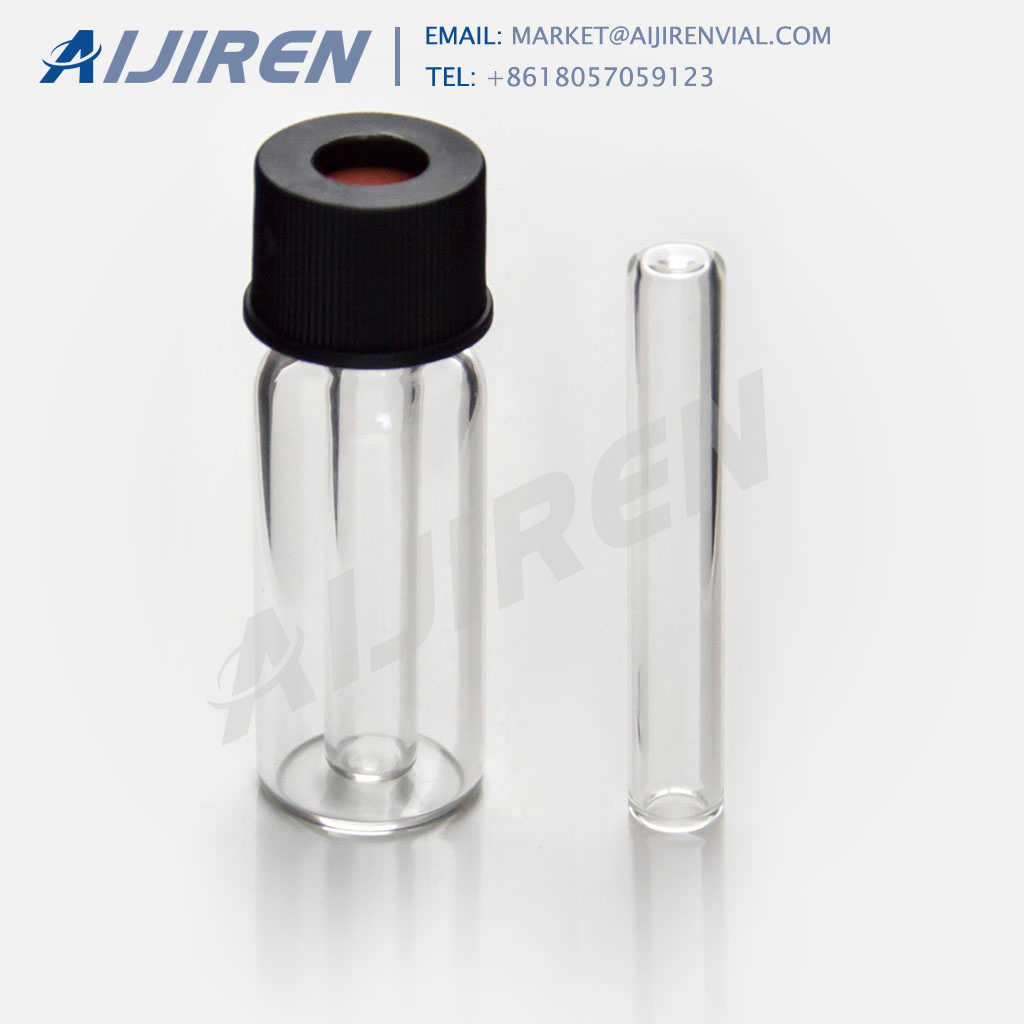

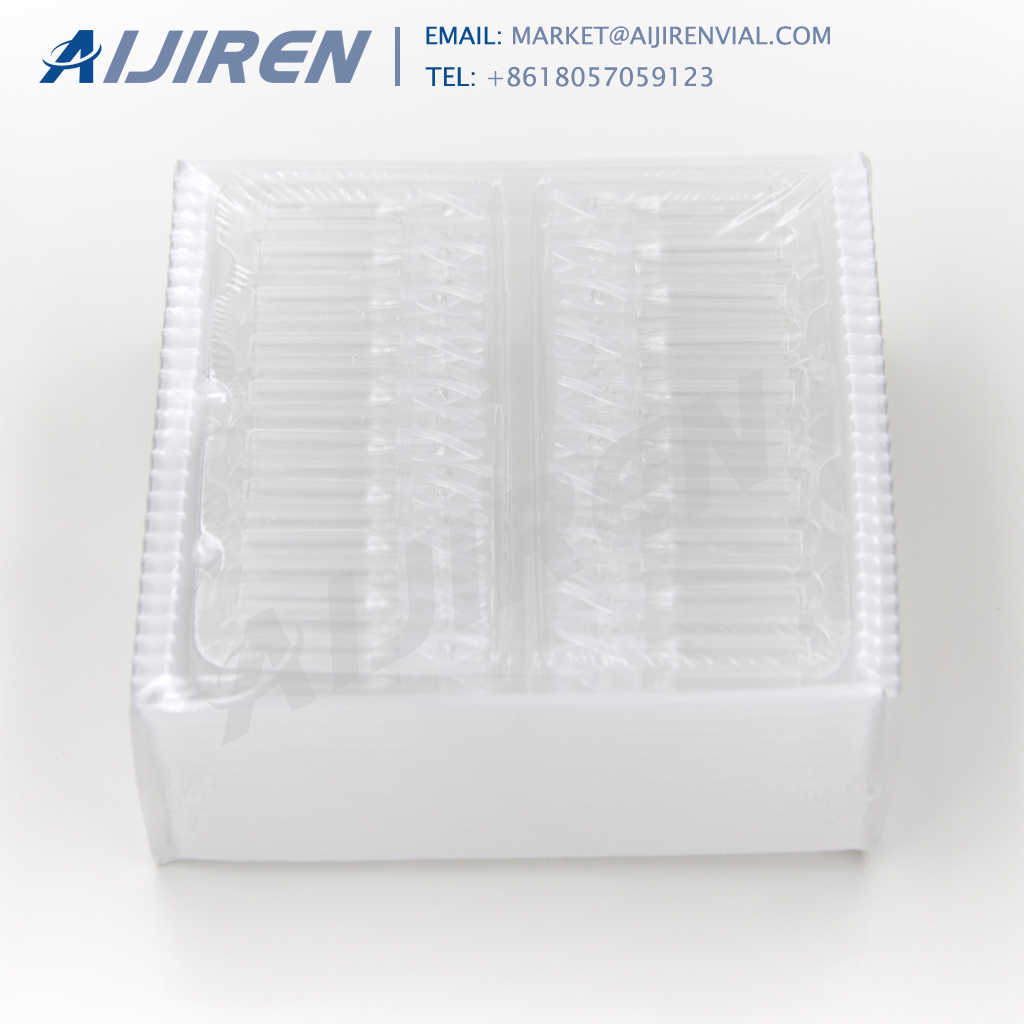

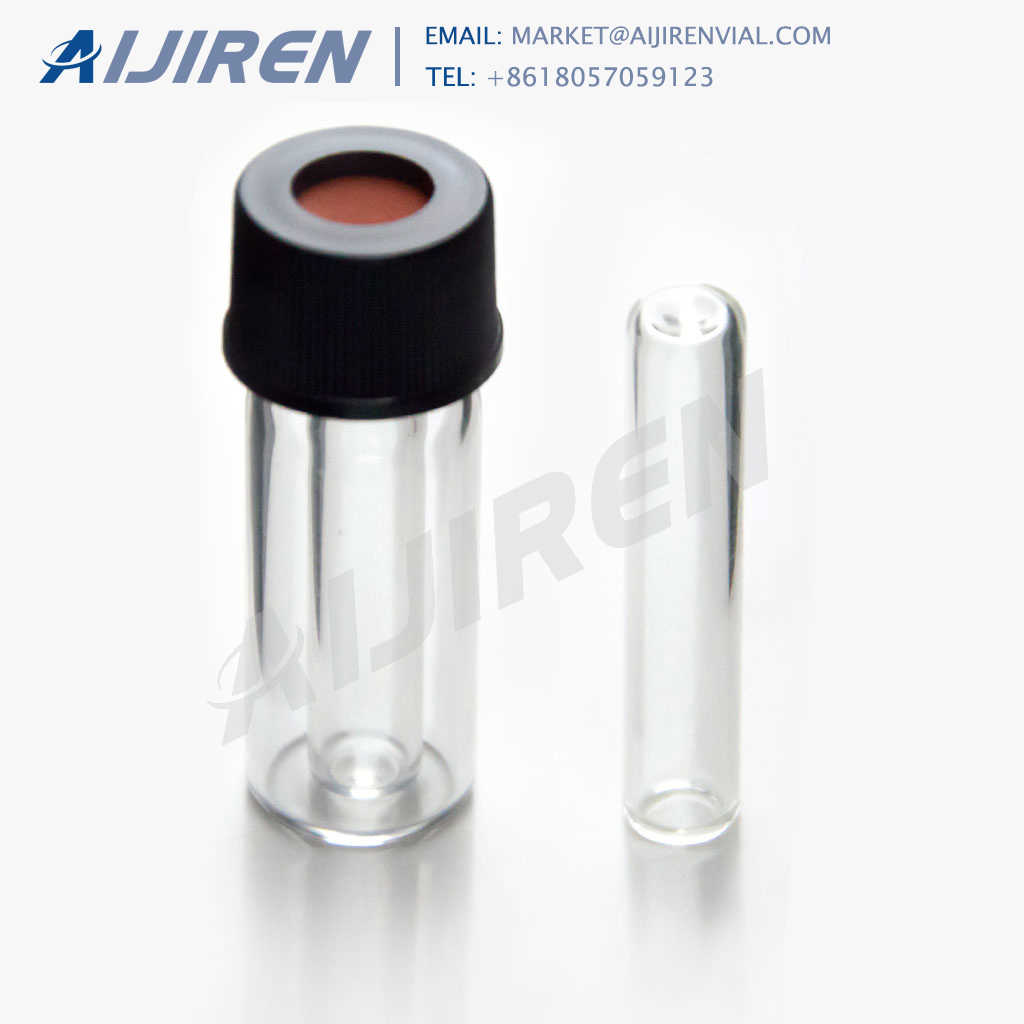

Conical Vial Insert, 250ul, 100/pk. IV250 vial insert. Conical Bottom. 31*5.7mm. suit for 9mm, 10mm, 11mm vials. 250uL insert 250ul vial insert conical bottom vial insert insert for hplc vials. Free Sample Get Price.

Insert components can include fasteners, couplings, filters, terminal connectors, pins, screws, shafts, subassemblies and metal stampings. INSERT MOLDING is typically characterized by molding these components, referred to as “inserts” directly into a part. These inserts are placed into the mold and then the plastic is injected into the

2019/12/13 · Insert molding is a specialized form of injection molding used to embed a plastic or metal component (the insert) into a final plastic product. Some inserts—such as wood and metal stiffening inserts—may be included solely for structural support, but others will add functionality to a product, such as threaded inserts.

250UL Inserts, Glass Inserts, Conical Inserts manufacturer / supplier in China, offering 250UL Glass Conical Inserts with Polymer Feet Replaces, 20mm Crimp-Top Blue Magnetic Aluminum Cap, Premium 2ml Autosampler Vial, 11mm Clear HPLC Crimp-Top Vial with Closure and so on. Send Inquiry Chat Now 6mm Conical Base Micro Insert For 2ml Hplc Vial -

10 Best Rv Molding Insert: Editor Recommended # Preview Product; 1: Camco 25212 Vinyl Trim Insert (1" x 100', Black) Buy on Amazon: 2: Insert Molding Solutions | Insert Molding Processes

Our overmolding and insert molding processes produce custom prototypes and on-demand production parts in as fast as 15 days. We use aluminum molds that offer cost-efficient tooling, producing parts from a range of thermoplastic and liquid silicone rubber materials. Overmolding and insert molding are frequently used for: low-volume production parts

2021/04/23 · Insert molding is molded together by the plastic molding process. So every part tightly molds in thermoplastic, an insert molded component prevents part loosening, mismatch, misalignment, and other problems. The plastic resin provides improved against shock and vibration. Increased design flexibility

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Simple to use and engineered for high productivity. Our latest generation of the most user friendly and compact ultra-precision CNC diamond turning lathe. Used for the rapid production of spherical & aspheric optical lenses, mirrors, mold inserts, freeform optics, and even mechanical components. If your application fits within a 350mm diameter

Here are some most familiar benefits of insert molding: 1. Assembly Cost Reduction Insert molding is a highly cost-effective manufacturing process. The foremost reason behind this is that it is a single-shot process only. Therefore, the need for post-molding assembly, which usually happens with the separate metal element, gets eliminated.

2022/02/28 · AdvanTech’s Insert Molding Capabilities The injection molding team at AdvanTech Plastics maintains a broad selection of insert molding capabilities. Armed with extensive experience and advanced manufacturing equipment, we can create high-quality molded plastic components for a variety of industries and applications.

250ul insert, polypropylene w/grad 100pk Add to Favorites + Create New list Item successfully added to your list List Price: $37.60 /100 Pack Add to cart Please enter valid quantity Specifications UNSPSC Code *

2021/11/19 · Film Insert Molding (FIM), also known as INS, is part of In-Mold Decoration. A technology that allows you to put virtually anything you want on a plastic component. The pre-printed film (or foil) is inserted into the mold cavity and thermoformed, which combines the advantages of decorative and functional graphics with a plastic molded component.