Jun 29, 2019 · In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the mold and what is placed inside the mold. A good example of a part manufactured on an insert molding machine is a Sub D Connector.

Insert-Molding Process. The video here demonstrates an automated robotic process for a recent insert-molding project at Ferriot. Shown are both the picking and placement of the insert as well as the picking of the finished part. For this project, the insert was a metal hinge pin. It was molded with plastic to create a door for another piece of

Dec 13, 2019 · There are three main techniques for encapsulating an insert: Multi-component injection molding, also known as co-molding, involves injecting some combination of multiple plastics and metals into the mold at the same time. These materials then join together, resulting in a stiffer, stronger piece. Multi-shot injection molding is similar to multi

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Insert Molding. Insert injection molding involves encapsulating a previously fabricated component in molten resin to produce a finished part. The inserted component is usually a simple object, such as a knife blade or surgical tube, but in some cases, inserts can be as complex as a battery or motor. Plastic insert molding is ideal for improving

Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.

Overmolding is a multi-step injection molding process where two or more components are molded over top of one another. Overmolding is sometimes referred to as two-shot molding because it is a two-step process. The two-step overmolding process. ( image source) First, a base component (otherwise known as a substrate) is molded and allowed to cure

INSERT MOLDING is typically characterized by molding these components, referred to as “inserts” directly into a part. These inserts are placed into the mold and then the plastic is injected into the cavity which encapsulates the insert. The result is a bi-component part. Depending on the design of both the plastic component and the insert

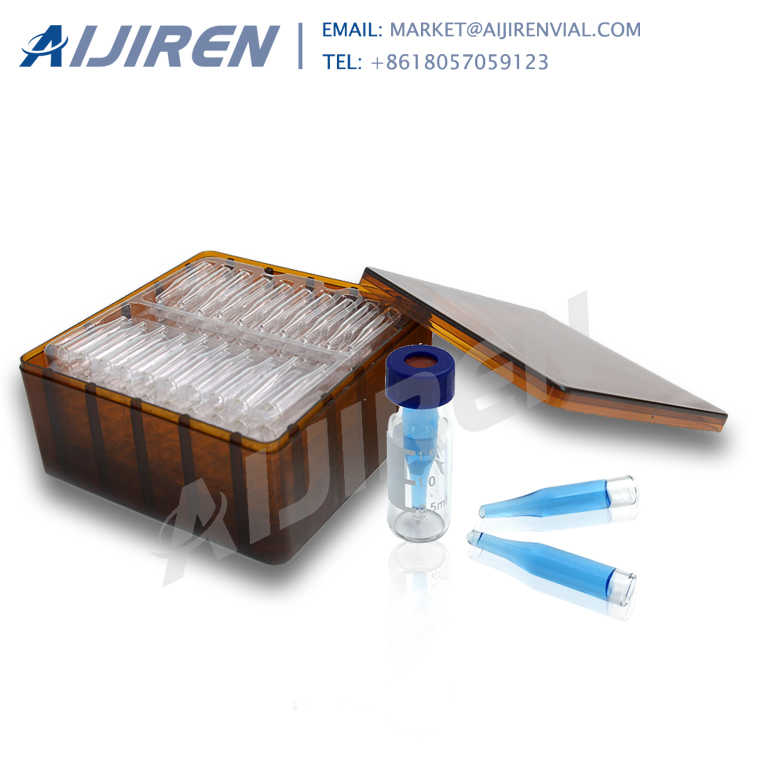

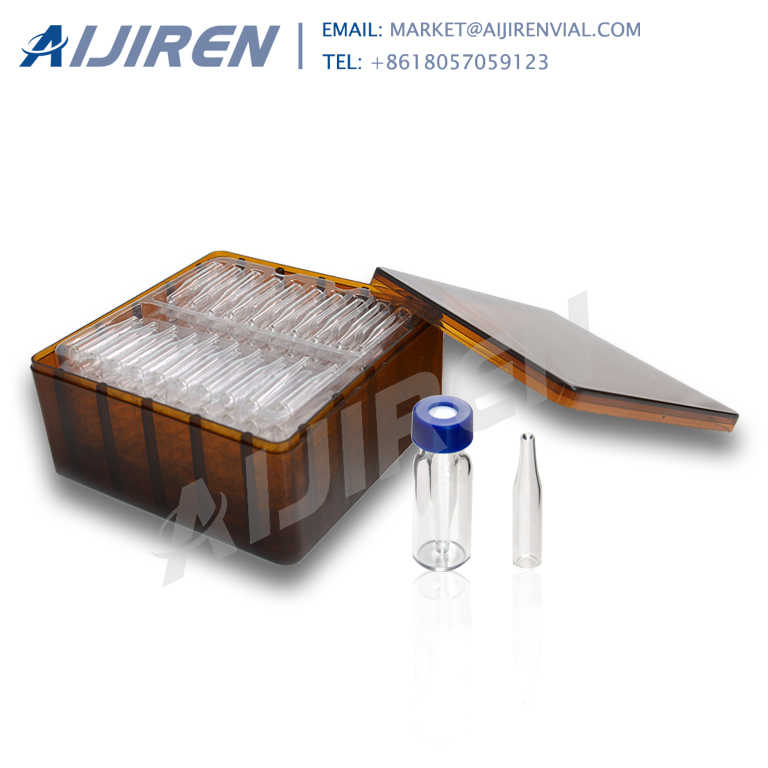

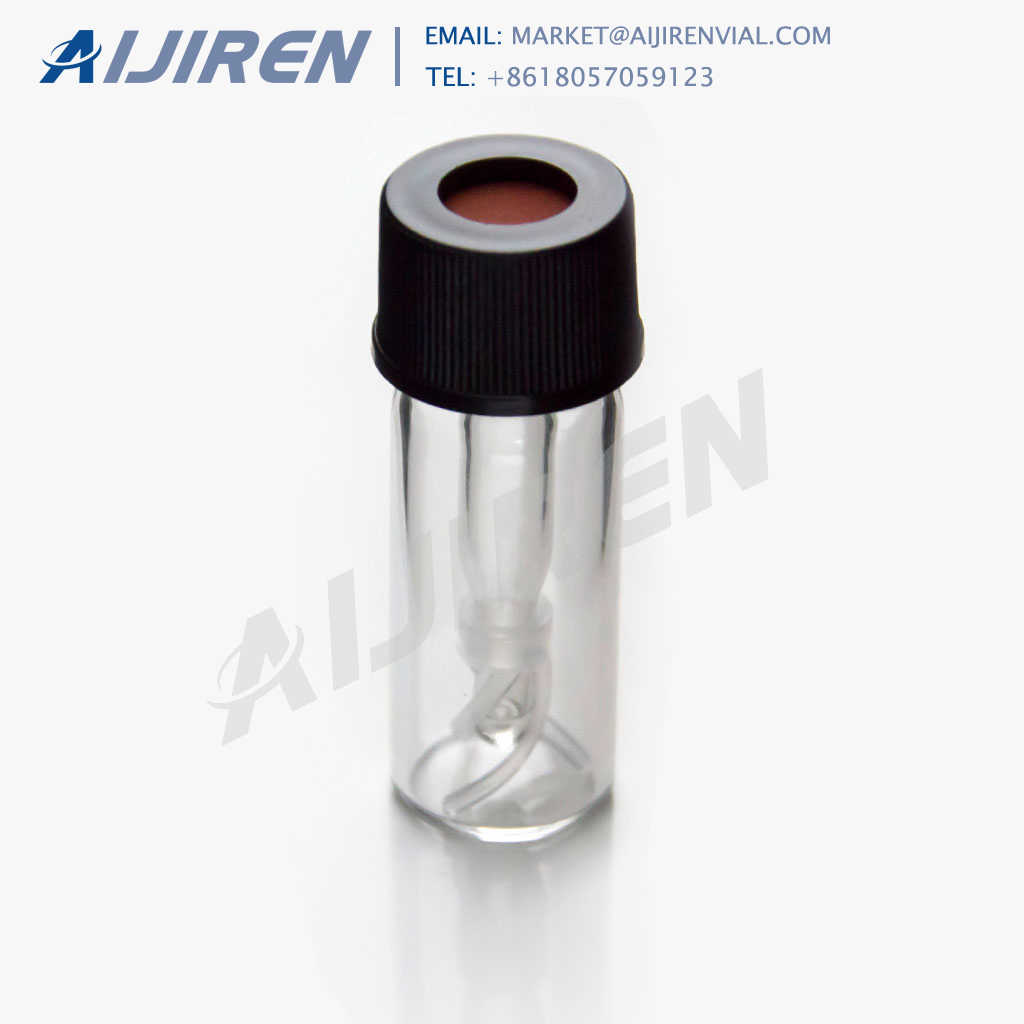

Standard Opening micro insert with mandrel interior and . IP250. 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9 Vials. I200. 200ul Micro-Insert,31*5mm,clear glass,flat bottom; suits for ND8 Vials. I300 Wholesales hplc insert with spring manufacturer Vial Inserts-Glass Inserts Manufacturer

Apr 28, 2021 · The insert molding process typically involves the incorporation of another material into a plastic component. This incorporation is to provide a localized hard point for locating or fastening components. Inserts are usually for providing a wear-resistant area for moving components. One of the most common forms of insert molding is the

Insert molding. The insert molding process conveys the idea that one piece or part is particularly made to be installed inside a larger injection mold, as an interior component or piece. As a result, the original piece or “insert” is transferred to another assembly space for integration with a larger plastic injection molded component.

Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

In this episode Gordon discusses the difference between Insert Molding and Two-Shot Injection Molding (aka) Overmolding (aka) 2K Molding, their advantages an

Aug 15, 2019 · Typically insert molding, or overmolding, requires accurately placing part(s) made from metal or other suitable materials (referred to as the insert) into the mold, closing the mold and then injecting the plastic into and/or around the insert(s). A typical application would be electrical connectors that incorporate machined metallic pins or sockets into a molded plastic housing. Most insert