网页2017/09/28 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features

网页2020/11/11 · Insert molding is a subset of injection molding techniques similar to overmolding where metal components are placed into a mold cavity before the actual plastic injection. The insert is precisely positioned inside the mold either manually or by a robotic arm. The mold then closes, and plastic is molded over the insert, creating a single part.

网页2019/12/13 · The first step is to create the tooling that will be used to form the product. This typically requires engineers to design a custom mold that resembles the finished shape

网页2021/11/19 · Film Insert Molding is a one-step process. This offers manufacturers extensive flexibility in design and manufacturing. The process includes 5 key stages : Printing Forming UV Curing Cutting or trimming Injection Moulding The media could not be loaded, either because the server or network failed or because the format is not supported.

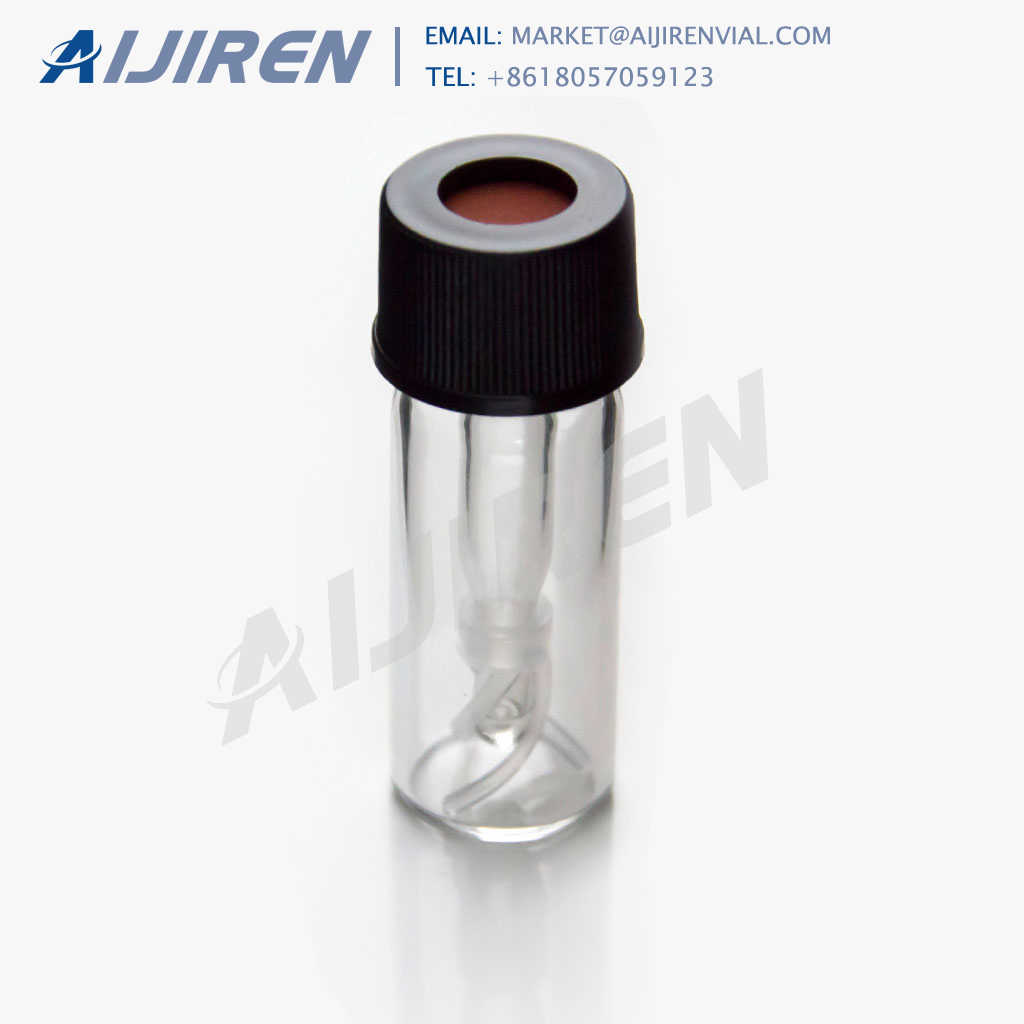

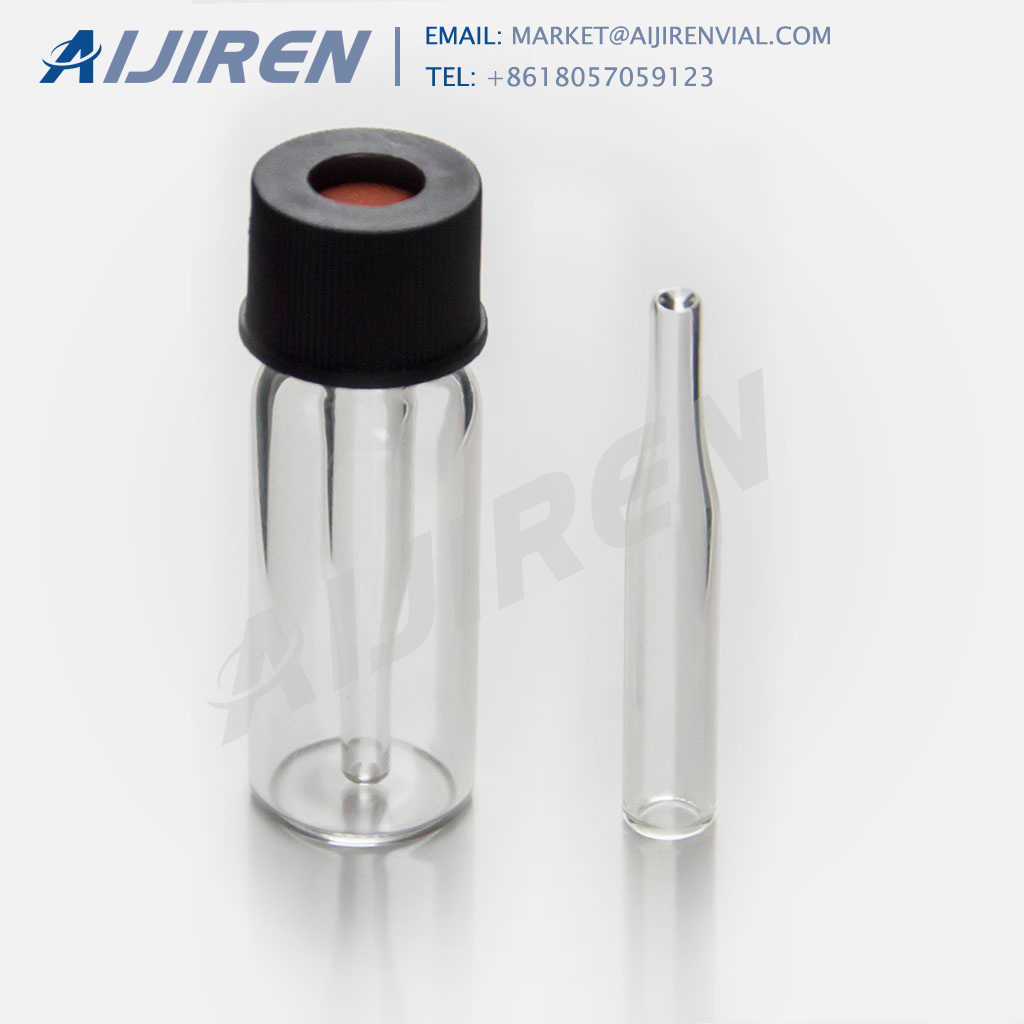

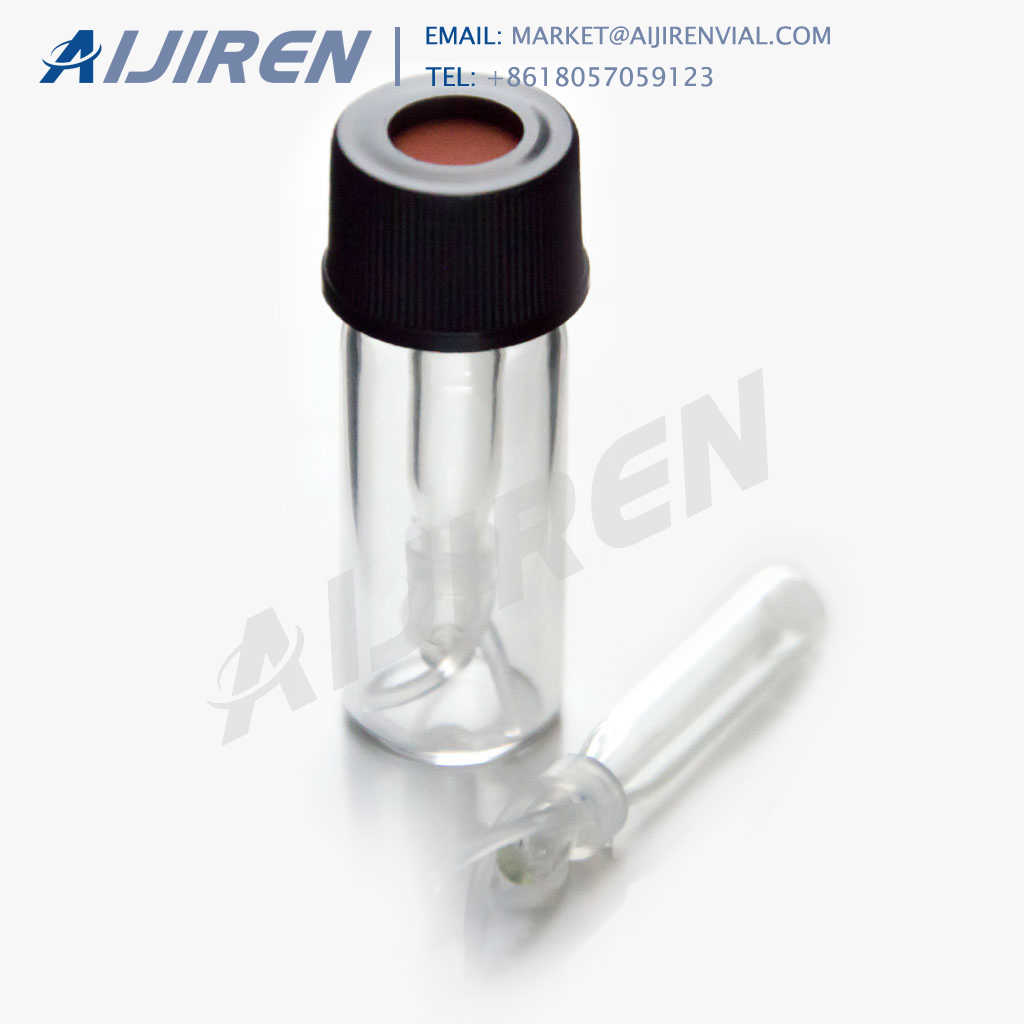

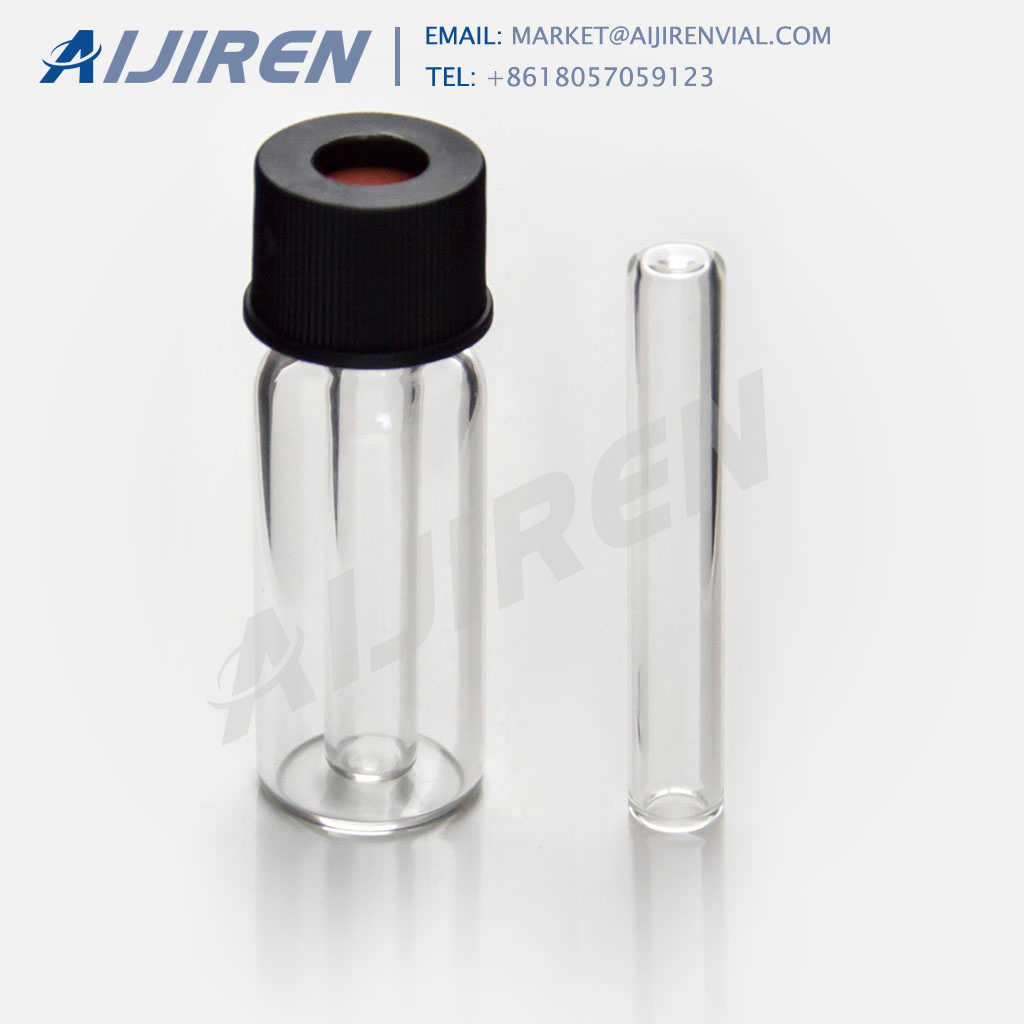

网页Definition. conical. the shaped interior bottom for your insert well "U" shaped. pulled point. visually appears squeezed at the bottom for reduced residual sample loss when withdrawing sample into injector. flat bottom. more obvious..no "v" shape at bottom; more box shaped..cheaper but more residual loss of sample. polymer feet.

网页Wabash Plastics’ automation engineers have years of experience developing fully automated insert molding systems that allow standard injection molding machines to be used. Our solutions result in direct labor savings and translate to a better quality part at a lower cost than the competition. Let our engineers evaluate your application today.

网页2020/03/11 · Insert Molding Insert molding is where the inserts are loaded into an injection mold before the molding process begins. Plastic is then injected around the insert to solidify it into place. The advantage of insert molding is that it does not require any secondary equipment (unlike some of the other methods listed below).

网页2021/07/01 · In this episode Gordon discusses the difference between Insert Molding and Two-Shot Injection Molding (aka) Overmolding (aka) 2K Molding, their advantages an

网页2020/07/06 · If a product is going to require screws, insert molding is one of the best solutions available. Using a threaded metal piece allows an otherwise plastic product to

网页2022/02/28 · Insert molding is an ideal manufacturing solution for many molded components. By combining the molding and assembly stages into a single process, it enables parts and products to be created in less time and at a lower cost. Additionally, the results often offer similar or better characteristics than components made through other

网页2021/03/06 · Essentially, you can get a 062″ diameter O-ring cross-section in the price tag of $1500 for a single cavity. Moreover, a two-cavity silicone injection mold can cost up to $2000. Molds for a complex gasket with undercuts along with complex geometry for insert and over-mold processes will charge you a cost of $6000 to $7500.

网页Insert molding and overmolding are two distinctly different processes that produce their own unique types of products. The overmolding process takes place when one material is overmolded over a second material. The base layer is molded first and the additional plastic layer (s) are molded over and around the original part.

网页2020/01/09 · Plastic parts need to be molded twice, but the product is only ejection once, usually by a set of molds. 3 types of mold structure According to moving different mold parts can be divided into: 1. Rotary Platen Multi-Shot Molding 2.Index Plate Multi-Shot Molding 3.Core Toggle Multi-Shot Molding Rotary Platen Multi-Shot Molding

网页2021/11/08 · Start Your Injection Mold Project with a Free Quote. Choose File. File Name. *Please upload your design or description file (Like:STP,DWG,PRT). Size limit is 20MB. +86-755-8524 1121. marketing@rydtooling.com. No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China.

网页Three Pin Plug Moulding Machine. Main Features: 1.Vertical clamping, vertical injection. 2.Compact design requires less floor space. Makes the take-out process more easilier. 3 Makes the take-out process more easilier. 4.Suitable for multi-purpose injection molding. Excellent for insert molding. Request Callback Additional Information: