Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

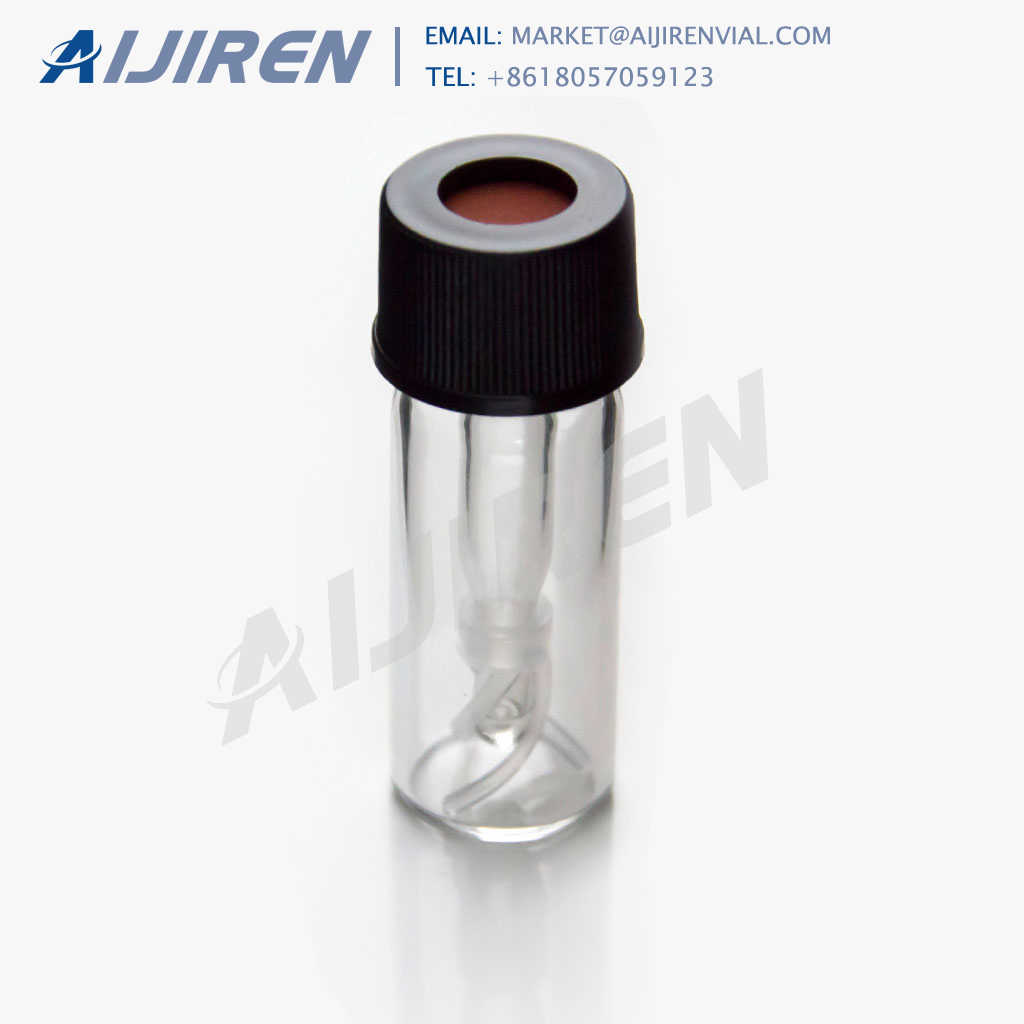

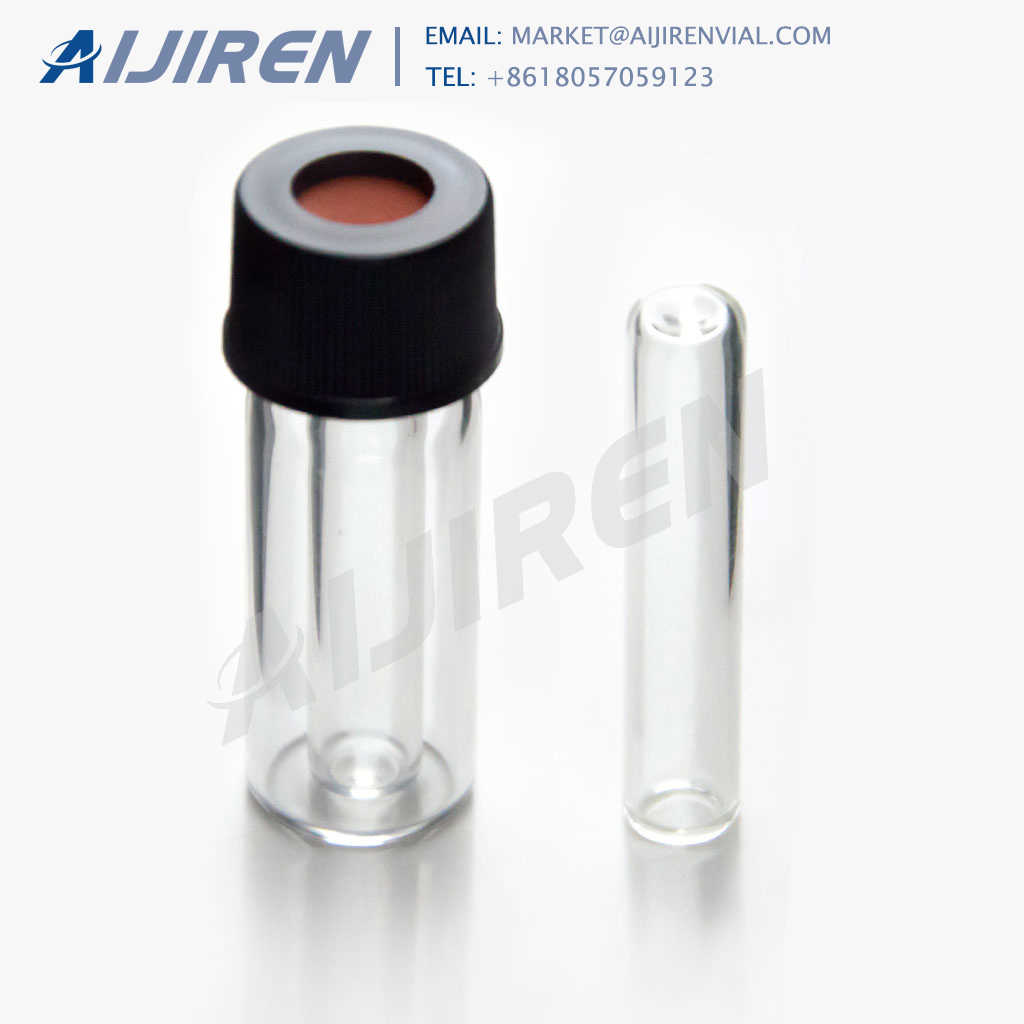

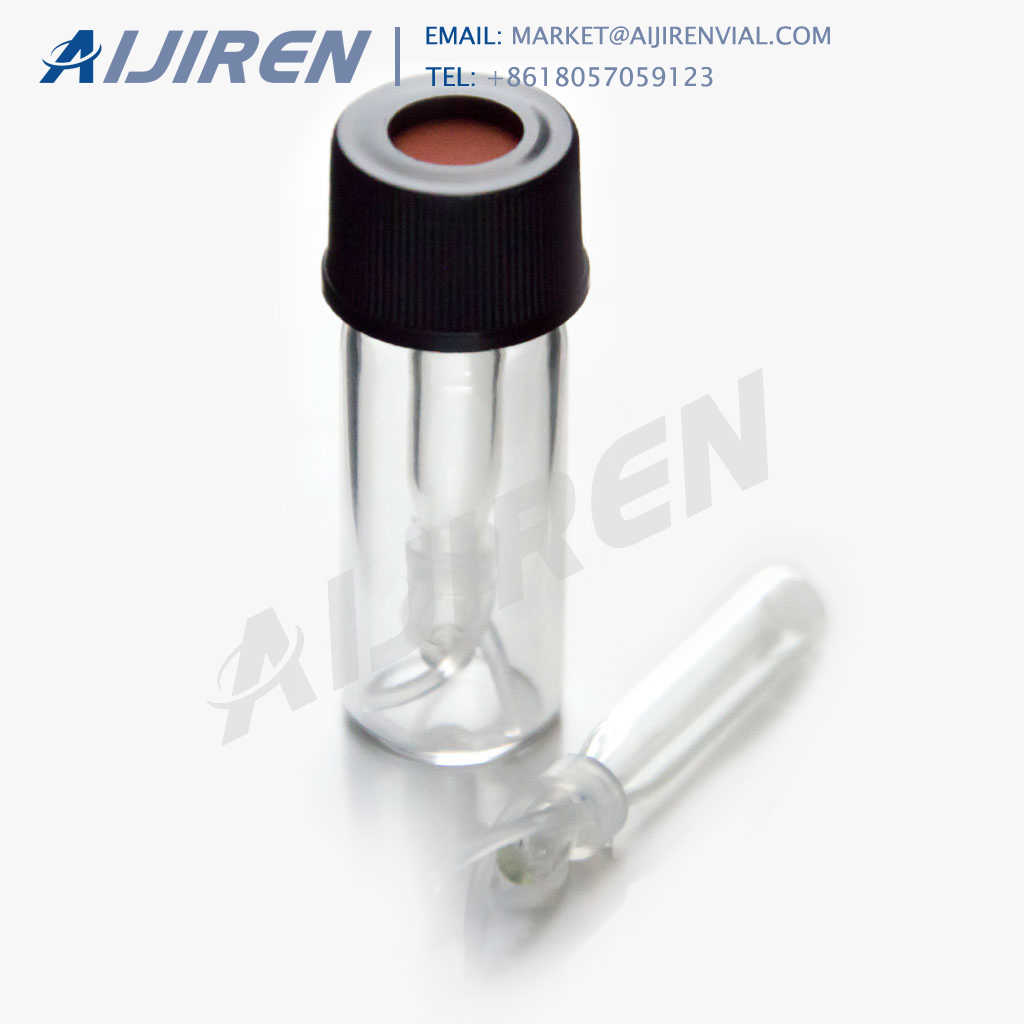

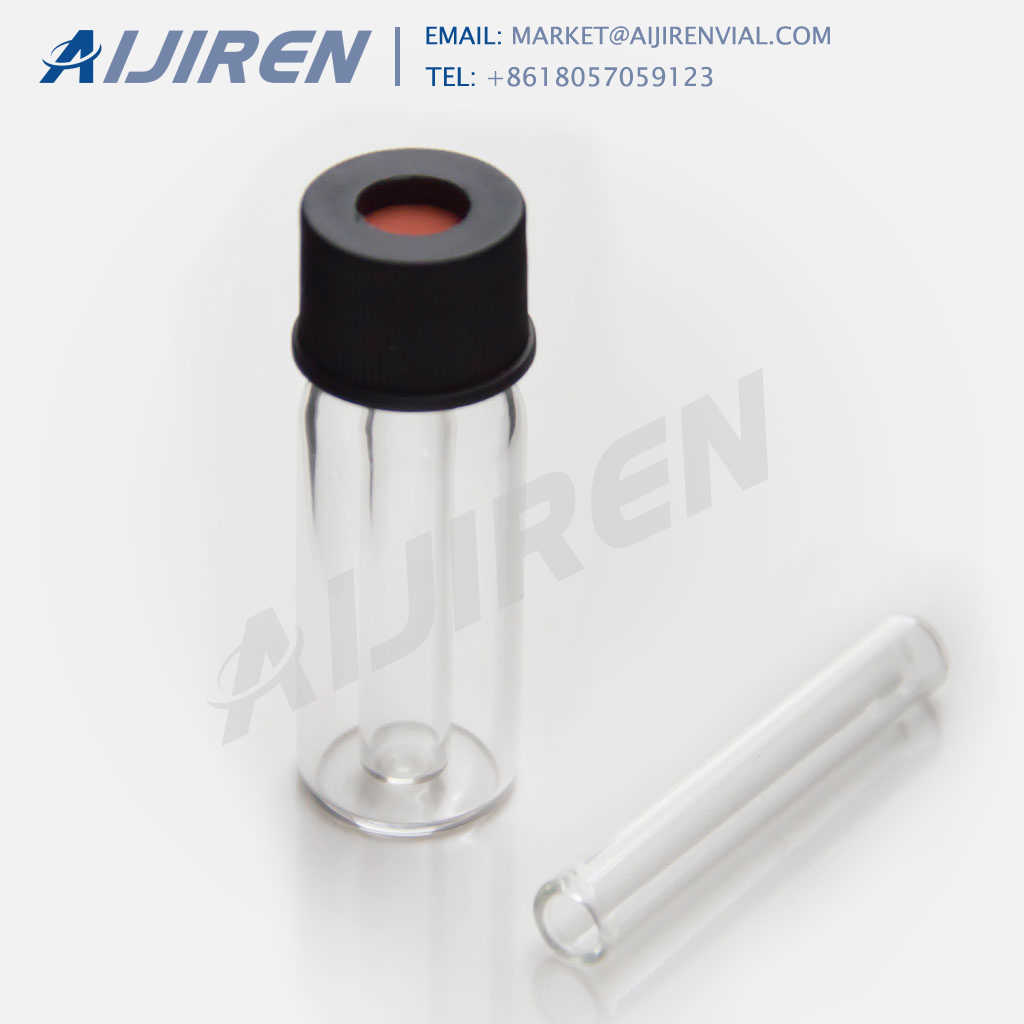

Sigma 250ul insert with mandrel interior and polymer feet for . Short Thread 9mm Clear Glass 1.5mL HPLC Autosampler Vials. 1 x 250uL Micro-Insert with Mandrel Interior and Polymer Feet, 29x5.7mm for 9mm vials, 100/pk, CV2044 + $16.38 1 x 250uL Micro-Insert, conical bottom, 31x6mm for 9mm vials, 100/pk, CV2046 + $10.96 1 x 300uL Micro-Insert, Flat Bottom, Clear, 31x6mm for 9mm vials, 100/pk

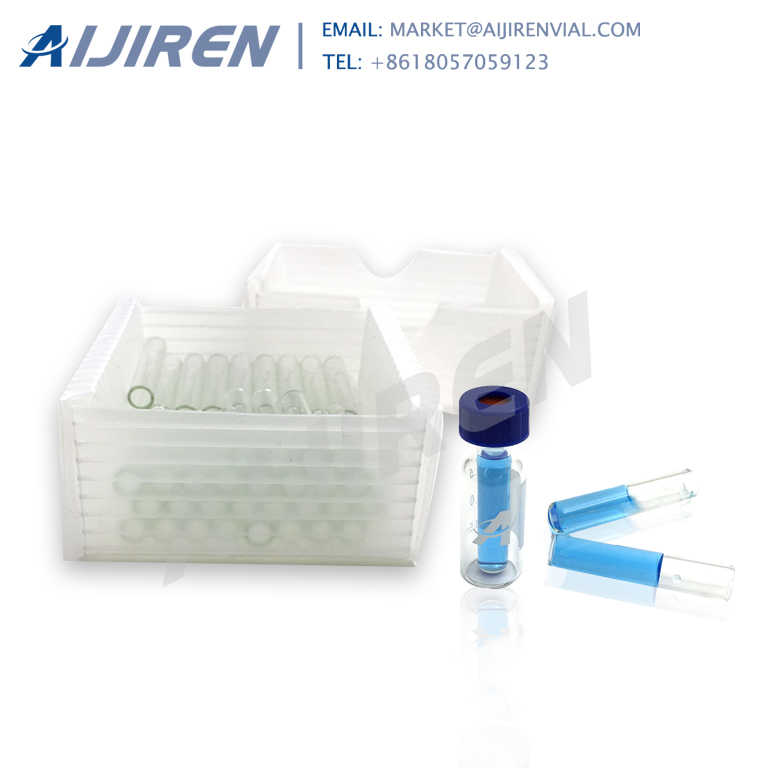

. Manufacturer: Aijiren Technologies. Description. Aijiren Vial insert, 300 uL, polypropylene, polymer feet. Do not fill to more than 250 uL, 100/pk Insert size: 5.6 x 30 mm - High Recovery Vials & Inserts. UNSPSC Code . - 58. Specifications.

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.

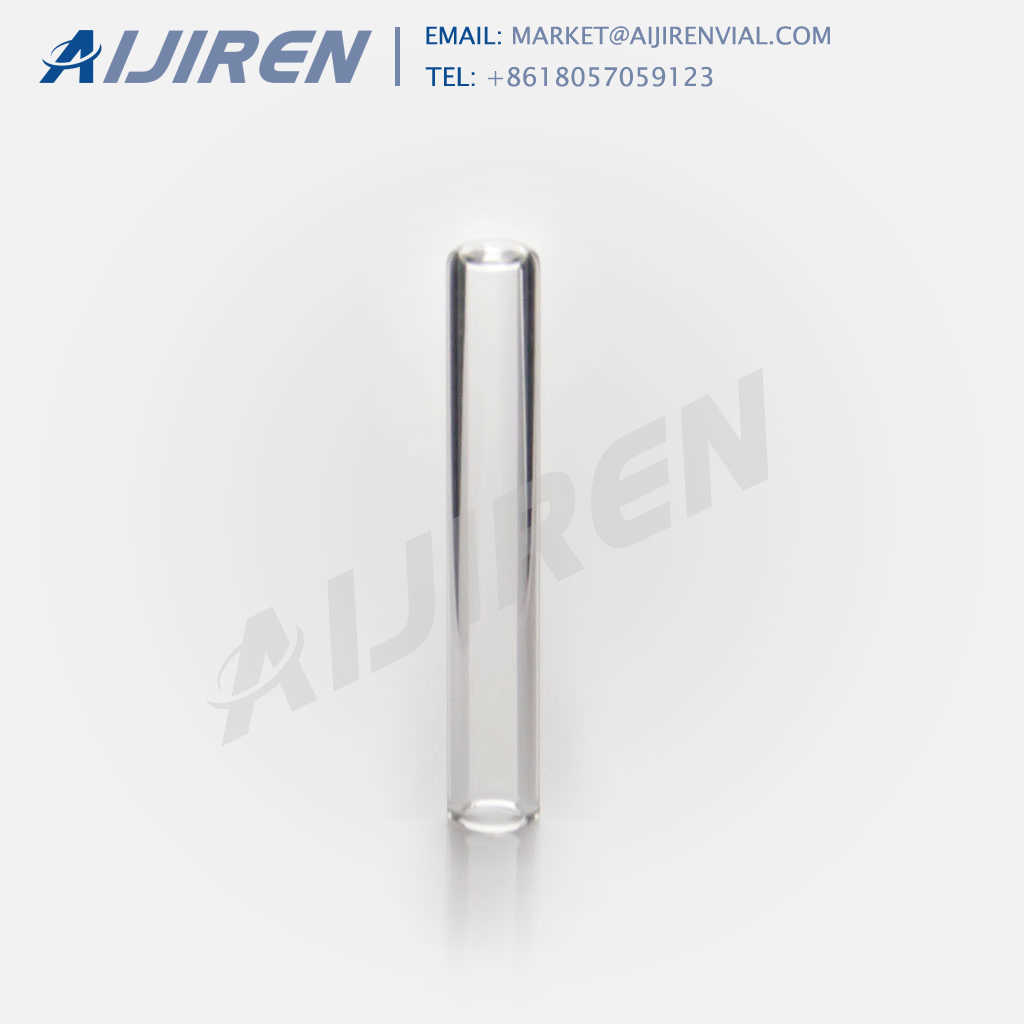

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal.

All conical styles of inserts are offered with the traditional pulled point as well as the improved mandrel point. Pulled point inserts are more economical, but mandrel point inserts provide a more pointed and uniform tip that enables better sample recovery. Micro-Inserts can be used on all 1.5ml vials. Effectively relieves the pressure of syringe.

Aug 15, 2019 · Typically insert molding, or overmolding, requires accurately placing part(s) made from metal or other suitable materials (referred to as the insert) into the mold, closing the mold and then injecting the plastic into and/or around the insert(s). A typical application would be electrical connectors that incorporate machined metallic pins or sockets into a molded plastic housing. Most insert

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Micro-Inserts are manufactured of clear glass. Vial insert with concial bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal because the conical shape decreases the surface area inside the vial. 250ul Vial inserts can be used for 9mm, 10mm, 11mm vials.

Short Thread 9mm Clear Glass 1.5mL HPLC Autosampler Vials. 1 x 250uL Micro-Insert with Mandrel Interior and Polymer Feet, 29x5.7mm for 9mm vials, 100/pk, CV2044 + $16.38 1 x 250uL Micro-Insert, conical bottom, 31x6mm for 9mm vials, 100/pk, CV2046 + $10.96 1 x 300uL Micro-Insert, Flat Bottom, Clear, 31x6mm for 9mm vials, 100/pk, CV2050 + $6.19.

250ul Clear Insert w/bottom spring 6x29, case/1000. List: $354.00 $329.47. Add to Cart. Quick view. Worldwide Glass Resources | sku: WWG-20051. 250ul Clear Insert w

Sep 13, 2021 · Insert molding vs. Overmolding On the surface, Insert Molding and overmolding seem to be very similar to each other, but there are some subtle differences between them. Contrary to insert molding, overmolding is a two-step process where a plastic component is molded over an already molded part to produce a single component.