J.G. Finneran Associates 250uL Glass Big Mouth Insert 4025BS-629. J.G. Finneran Associates authorized distributor . ☎ (800) 970-3646 Mon-Fri 8.00-17.00 ET or order online 24/7 J.G. Finneran Associates, 4025BS-629 – 250uL Glass Big Mouth Insert Volume: 250 uL, Vial Type: with Bottom Spring | Lab Equipment Depot. Send Inquiry.

Process steps for double-sided molding. •. The mold inserts are applied to the cooling blocks. In this way, cooling of the mold inserts is started (step 1). By the closing movement of the tool, the clamping rings are moved synchronously with the upper mold insert, which prevents the semifinished product from being stretched at the edge of the

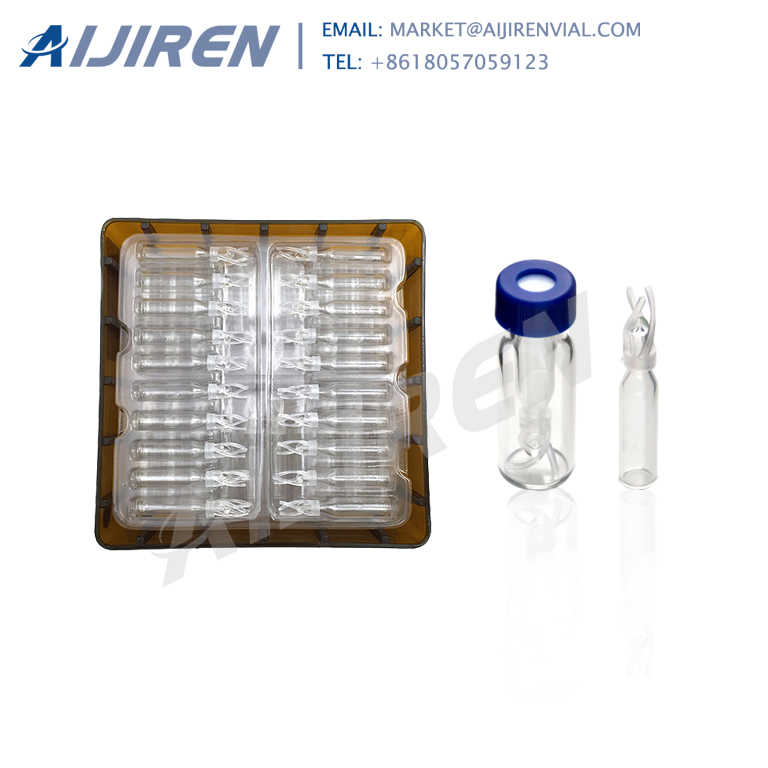

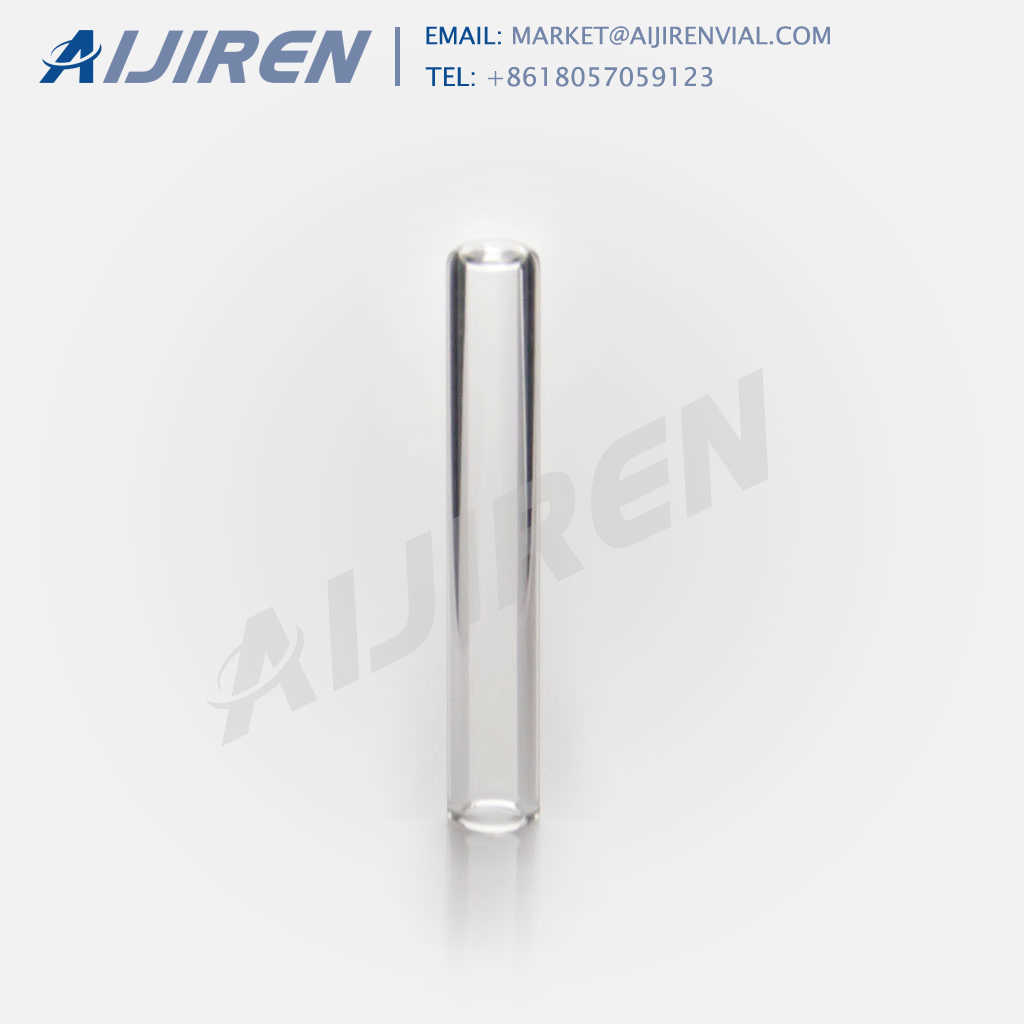

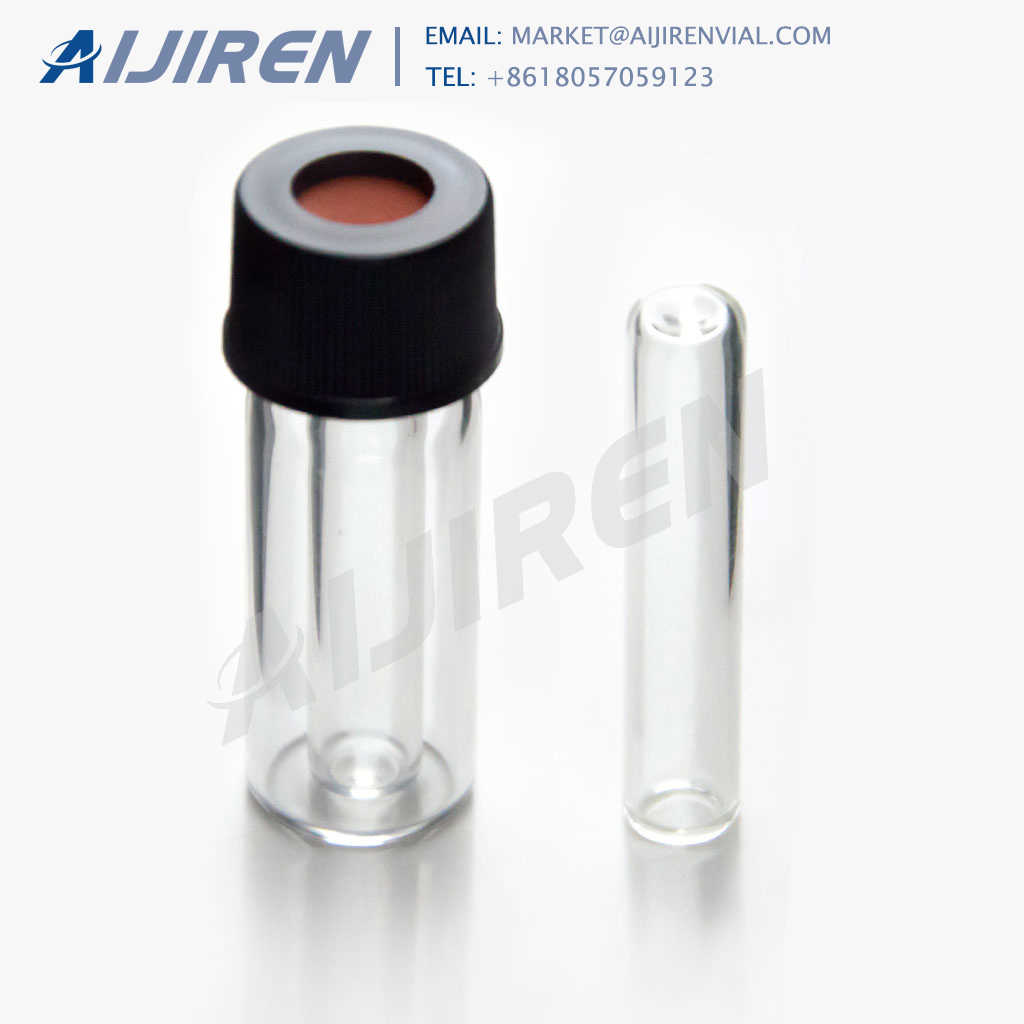

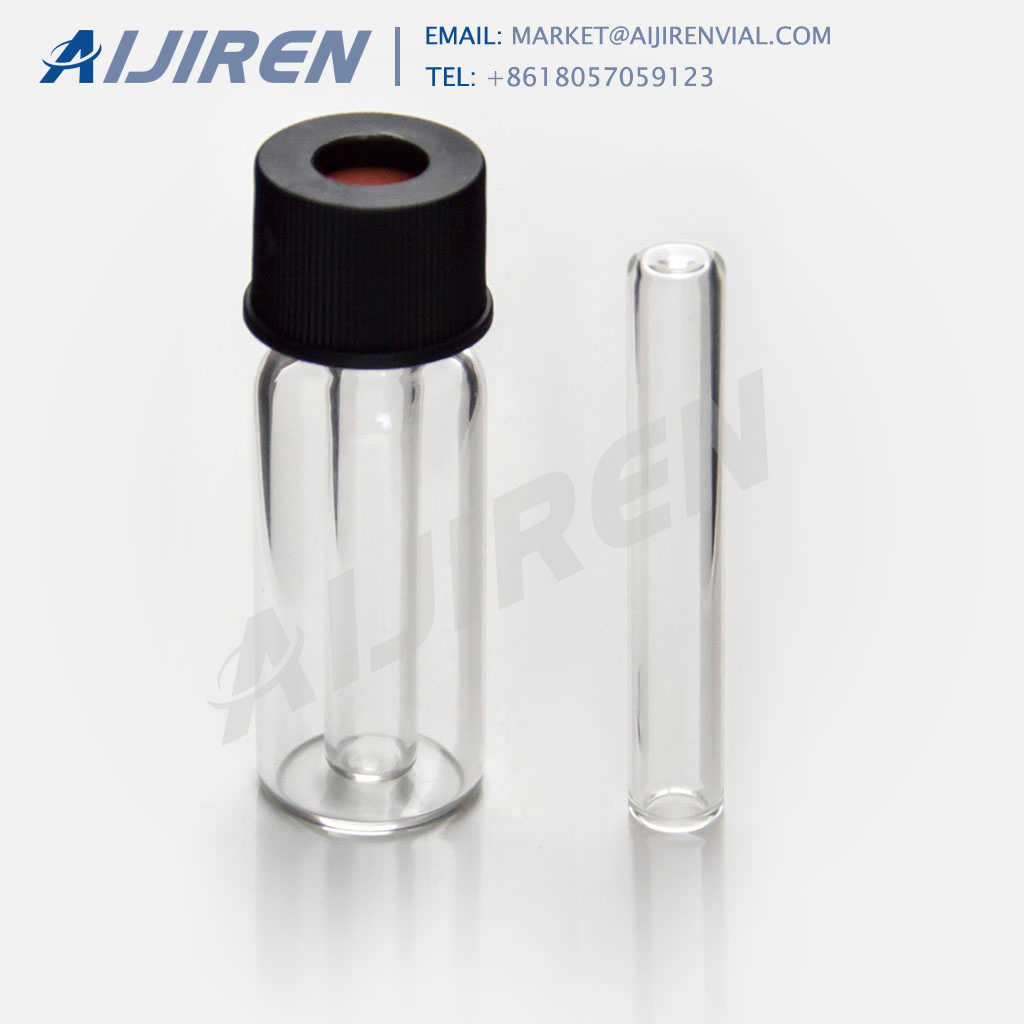

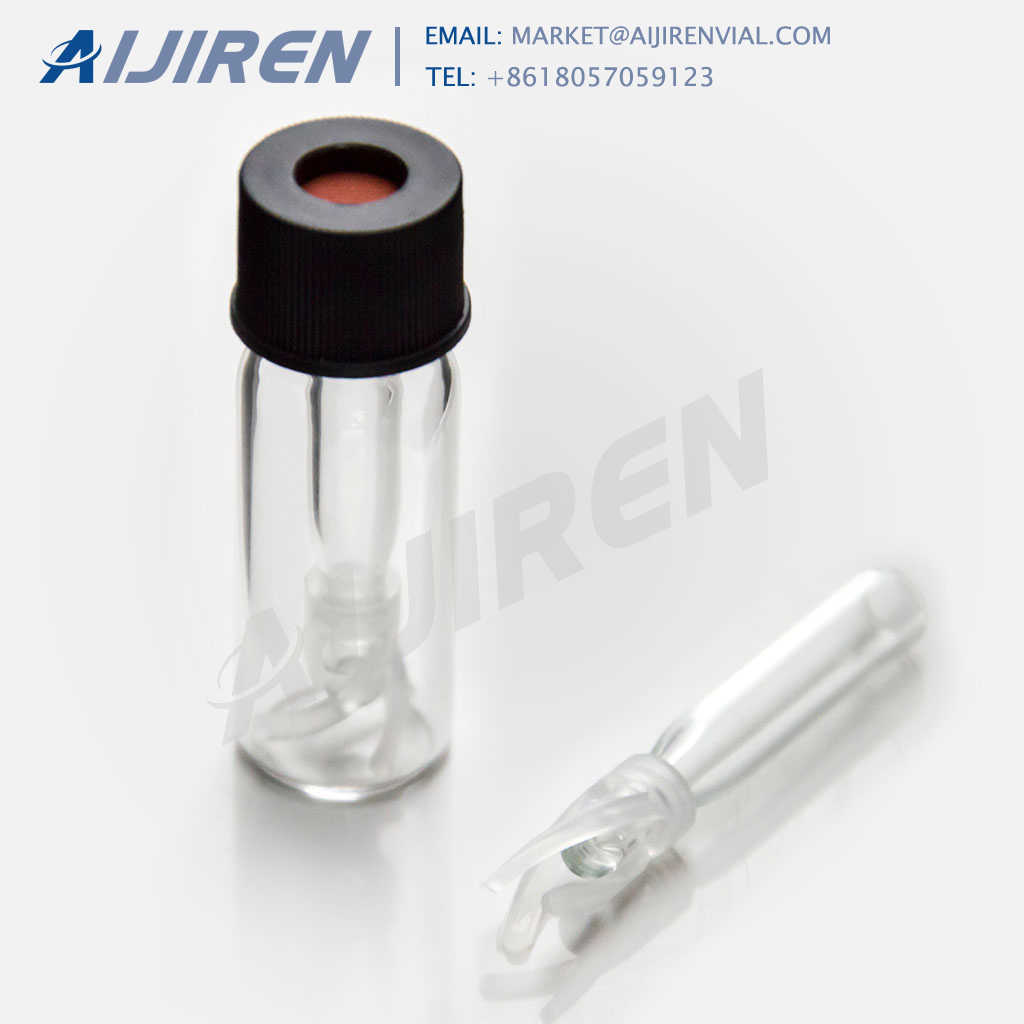

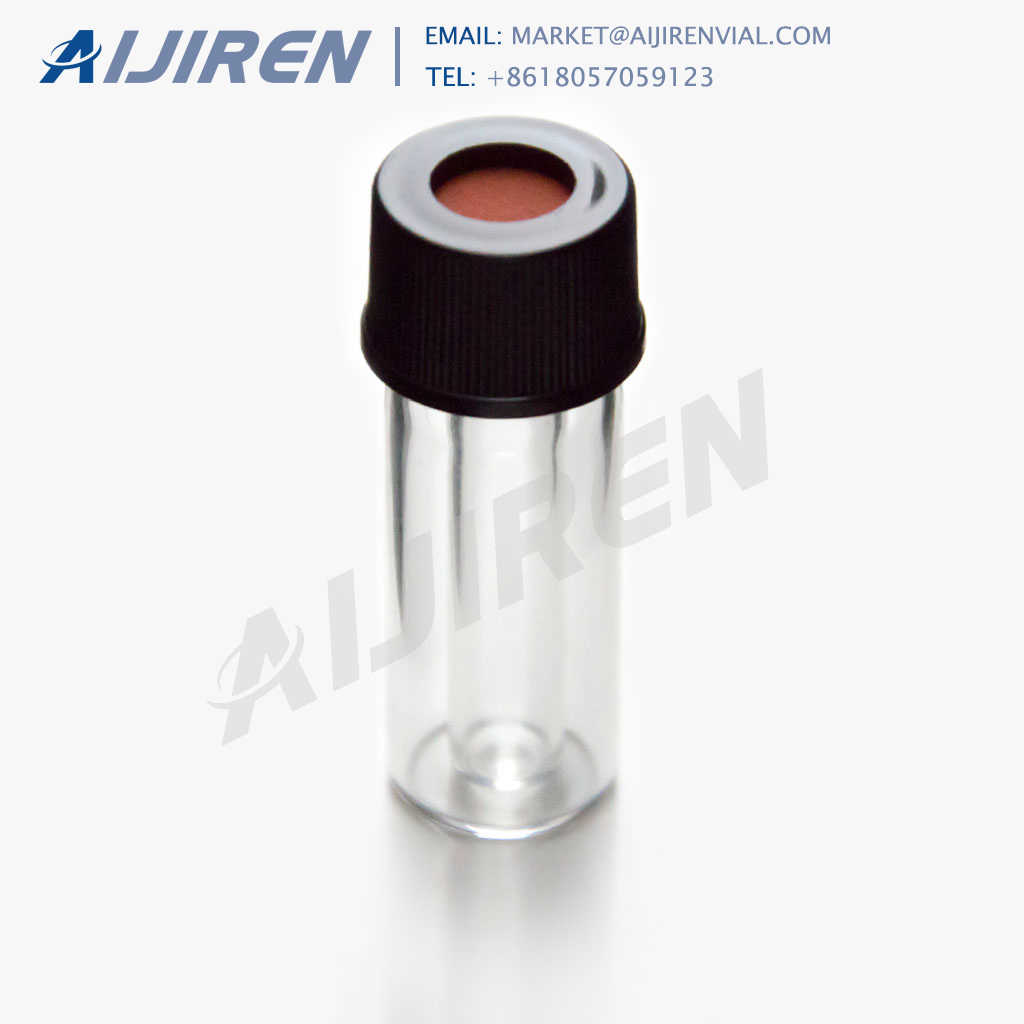

Sigma 250ul insert with mandrel interior and polymer feet for Short Thread 9mm Clear Glass 1.5mL HPLC Autosampler Vials. 1 x 250uL Micro-Insert with Mandrel Interior and Polymer Feet, 29x5.7mm for 9mm vials, 100/pk, CV2044 + $16.38 1 x 250uL Micro-Insert

2019/7/16 · In short, overmolding and insert molding are both subsets of a manufacturing process known as injection molding. These two subsets contain the same molding process of injecting plastic resin into a mold cavity, but they have one minor difference that people often ignore: all overmolding is insert molding, but not vice versa. Now, to understand

Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

2021/4/23 · The Insert Molding process starts off by either inserting the metal inserts before the custom injection molding process, or they can be inserted during the custom injection molding process . If the inserts are chosen to be inserted during the plastic injection molding process, an Insert Moulding process operator or a robotic arm will load them.

2021/4/28 · Insert molding can also create the functional strain reliefs found on most cables (To learn about strain reliefs more in-depth, give our article a read). Ease of assembly - Electrical contacts are set as inserts in the injection molding process. This eliminates the

Various types of inserts come with their own benefits and drawbacks, so contact Romeo RIM today for help deciding just which insert is right for your next project! 74000 Van Dyke Ave, Romeo, MI 48065. 586-336-5800 Mon-Fri, 8am until 5pm EST. sales@romeorim.com We reply within 48 hours. Tags: Insert Molding.

Insert Molding Analysis, Mold Insert, Injection Molding Table 1. Insert materials list Insert # Material Cp (erg/g.K) K (erg/sec.cm) 1 P6 4.6e6 4.7e7 2 Beryllium_Copper 1.9e7 1.5e7 3 Polymer 2.3e7 2.4e4 Figure 1. Computational framework of 3D injection

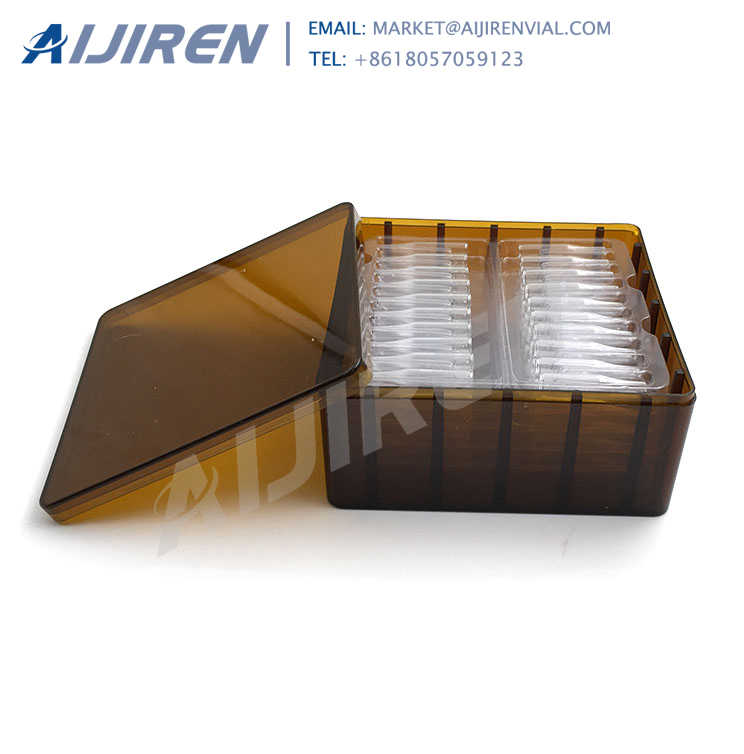

Home » News » Micro insert » 250ul insert manufacturer from Alibaba Products List 1-4mL Autosampler Vials for HPLC, UPLC, GC 6-20mL GC Headspace Vials 8-60mL EPA Storage Vials 16mm, 25mm Test Tubes for Water Analysis HPLC Syringe Filters

Tags: Insert Molding. 250ul insert for Aijiren from Aijiren-Aijiren HPLC Vials Vial Insert, 250 uL, Glass, conical with Polymer feet, 100/pk. Aijiren Technologies Item Weight: 2.12 ounces Model Number: 77 Number of Items Vial insert, 250 uL, glass with polymer

Ferriot’s capacity demonstrates our core expertise in injection molding. From the simplest geometries and lightest-weight components to the most complex shapes and 20-pound parts, we have the experience to manufacture the parts you need. With a clamping force capacity of 40 to 2,200 tons, we will meet the force requirements of your project.

Insert Molding 埋入射出 Precision Molding 精密模具 Company Introduction 公司簡介 Contact Us 聯絡我們 選單 Insert Molding 埋入射出 Advantages: 優點: Combine plastic injection with metal, pin, and brassetc 結合塑膠射出與金屬材料、金屬彈片、黃銅等

Designing insert molds flows are a standard process that has to be followed strictly to increase chances of success. The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the

262-594-5050. Specialties. New Product Design/Development. Plastic Injection Molding Consulting. Mold Design Services. Plastic Injection Molding. Plastic Overmolding. Insert Molding. Plastic Welding.