2021/11/19 · Film Insert Molding (FIM), also known as INS, is part of In-Mold Decoration. A technology that allows you to put virtually anything you want on a plastic component. The pre-printed film (or foil) is inserted into the mold cavity and thermoformed, which combines the advantages of decorative and functional graphics with a plastic molded component.

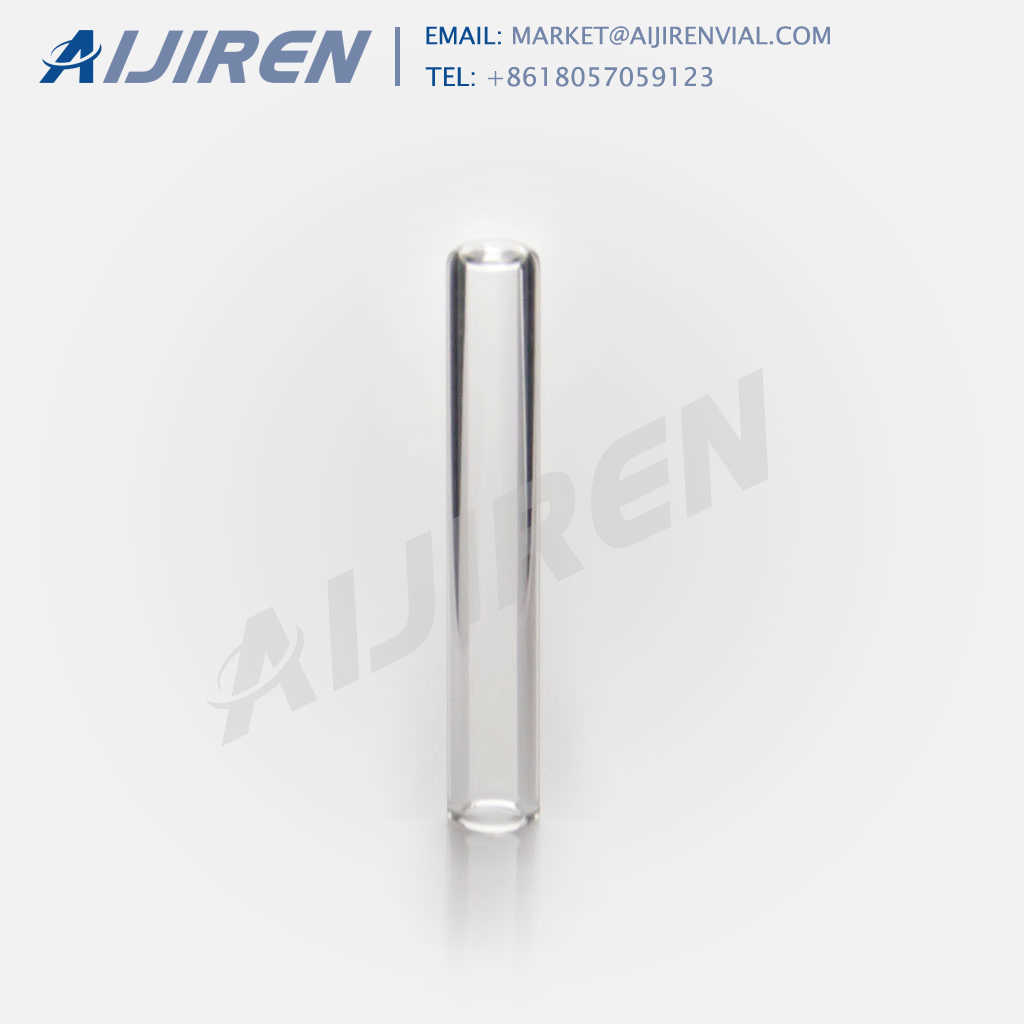

Sigma 250ul insert with mandrel interior and polymer feet for Short Thread 9mm Clear Glass 1.5mL HPLC Autosampler Vials. 1 x 250uL Micro-Insert with Mandrel Interior and Polymer Feet, 29x5.7mm for 9mm vials, 100/pk, CV2044 + $16.38 1 x 250uL Micro-Insert

Caps are made of high quality polypropylene to exact manufacturing tolerances and lined in a controlled manufacturing environment. suits for ND8 Vials IPB250 29*5.7mm 100PCS/PK 250ul Insert with mandrel interior and polymer feet, 29*5.7mm; suits for ND9

Insert molding and overmolding are two of our specialties, techniques mastered by only the most detail-oriented plastic injection molders. In the case of insert molding, we place an object in the mold and inject plastic around the component to form a mechanical bond. In the case of elastomeric overmolding of hard plastic, the bond is also

Medical Polymers, Inc., Spencer, IN. Insert molding is an injection molding process whereby plastic is injected into a cavity and around an insert piece placed into the same cavity just prior to molding. The result is a single piece with the insert encapsulated by the plastic. The insert can be made of metal or another plastic.

2022/4/2 · Insert molding is a subset of injection molding techniques similar to overmolding where metal components are placed into a mold cavity before the actual plastic injection. The insert is precisely positioned inside the mold either manually or by a robotic arm. The mold then closes, and plastic is molded over the insert, creating a single part.

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal.

Insert Molding Analysis, Mold Insert, Injection Molding Table 1. Insert materials list Insert # Material Cp (erg/g.K) K (erg/sec.cm) 1 P6 4.6e6 4.7e7 2 Beryllium_Copper 1.9e7 1.5e7 3 Polymer 2.3e7 2.4e4 Figure 1. Computational framework of 3D injection

Designing insert molds flows are a standard process that has to be followed strictly to increase chances of success. The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the

2021/4/28 · Insert molding can also create the functional strain reliefs found on most cables (To learn about strain reliefs more in-depth, give our article a read). Ease of assembly - Electrical contacts are set as inserts in the injection molding process. This eliminates the

Insert molding vs overmolding. Overmolding is a process by which two or more different materials are used to create a single product. Overmolding allows manufacturers to create pieces that combine the strengths of different plastics. One common example would be a simple toothbrush, featuring a hard plastic core and a soft, rubber-like grip.

Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. View our design guidelines page for more in-depth details. US. Metric. Maximum Part Size. 18.9 in. x 29.6 in. x 8 in. 480mm x 751.8,, x 203.2mm.

Aijiren 250ul insert for gc vials-Aijiren HPLC Vials Uvison.com Aijiren Vial Inserts 250 µL Polypropylene Insert - - with polymer feet, 100/pk Microvolume Inserts To meet your microsampling needs, Aijiren has a variety of microvolume inserts with capacities and designs that transform our vials from full-capacity to limited volume with one simple step.

Sigma 250ul micro insert vial exporter-HPLC Vial Inserts High Recovery Vials and Inserts | Aijiren. hplc vial inserts for sale. Micro-Inserts--HPLC Vial Inserts. 250uL Micro-Insert with Mandrel Interior & Polymer Feet, 29*5.7mm, Suits for 9mm Vials 3. 10-425 Vilas Micro-Inserts Part No. I300 IV250-I(Economy) IV250 IP250-I(Economy) IP250 Description 300uL Micro