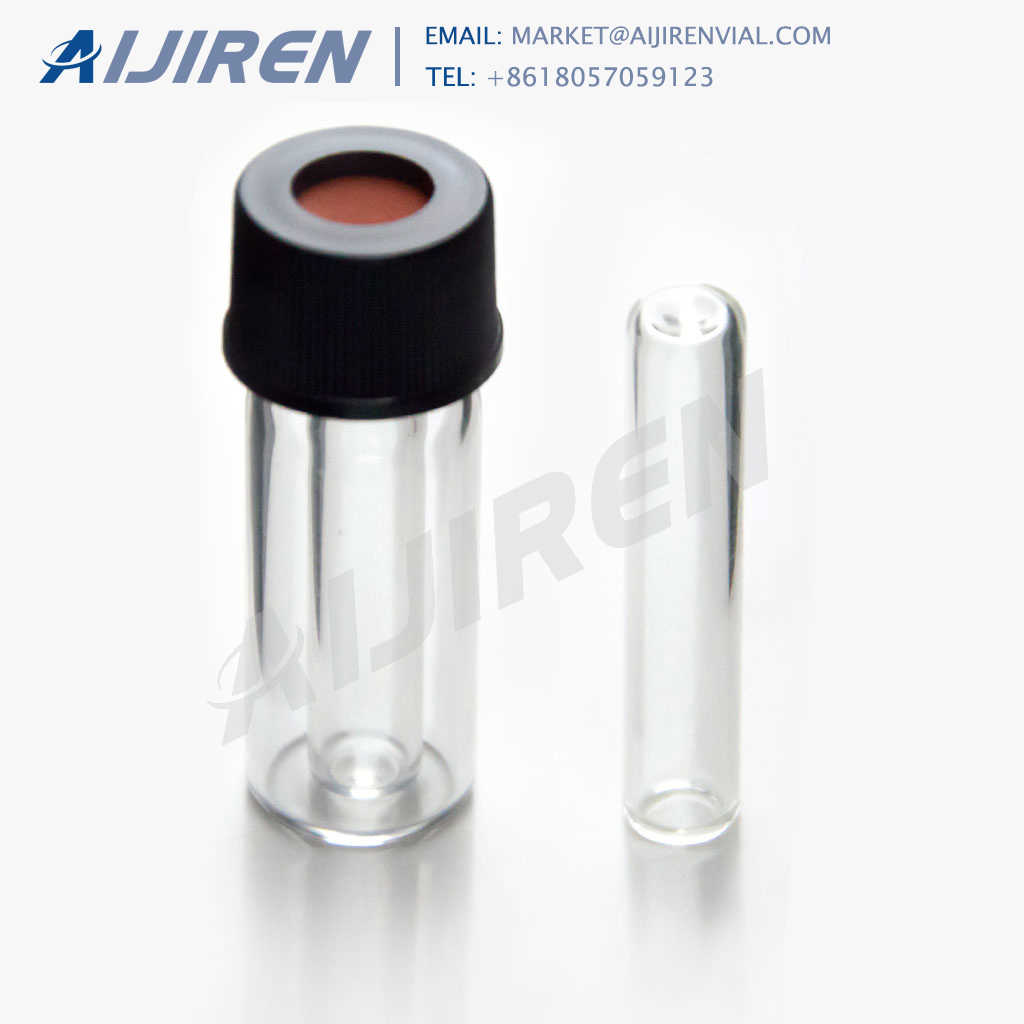

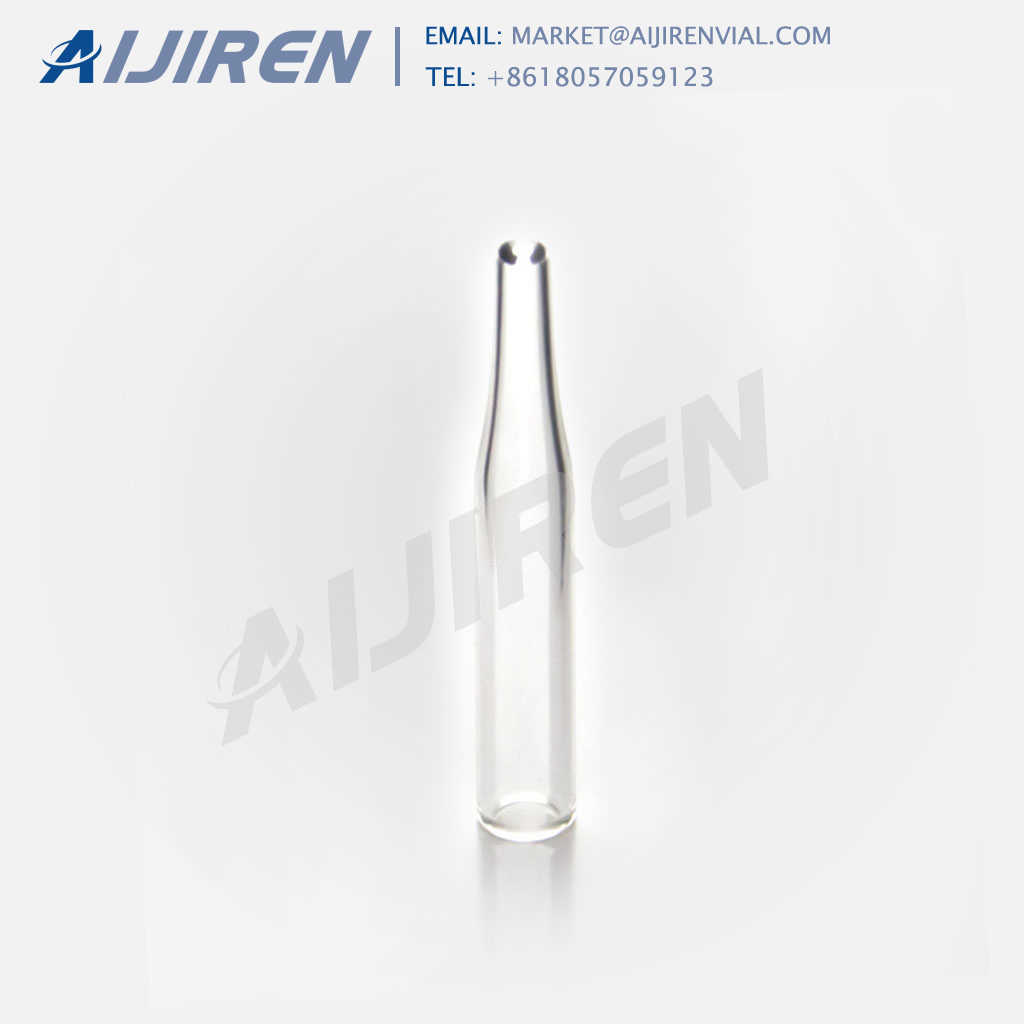

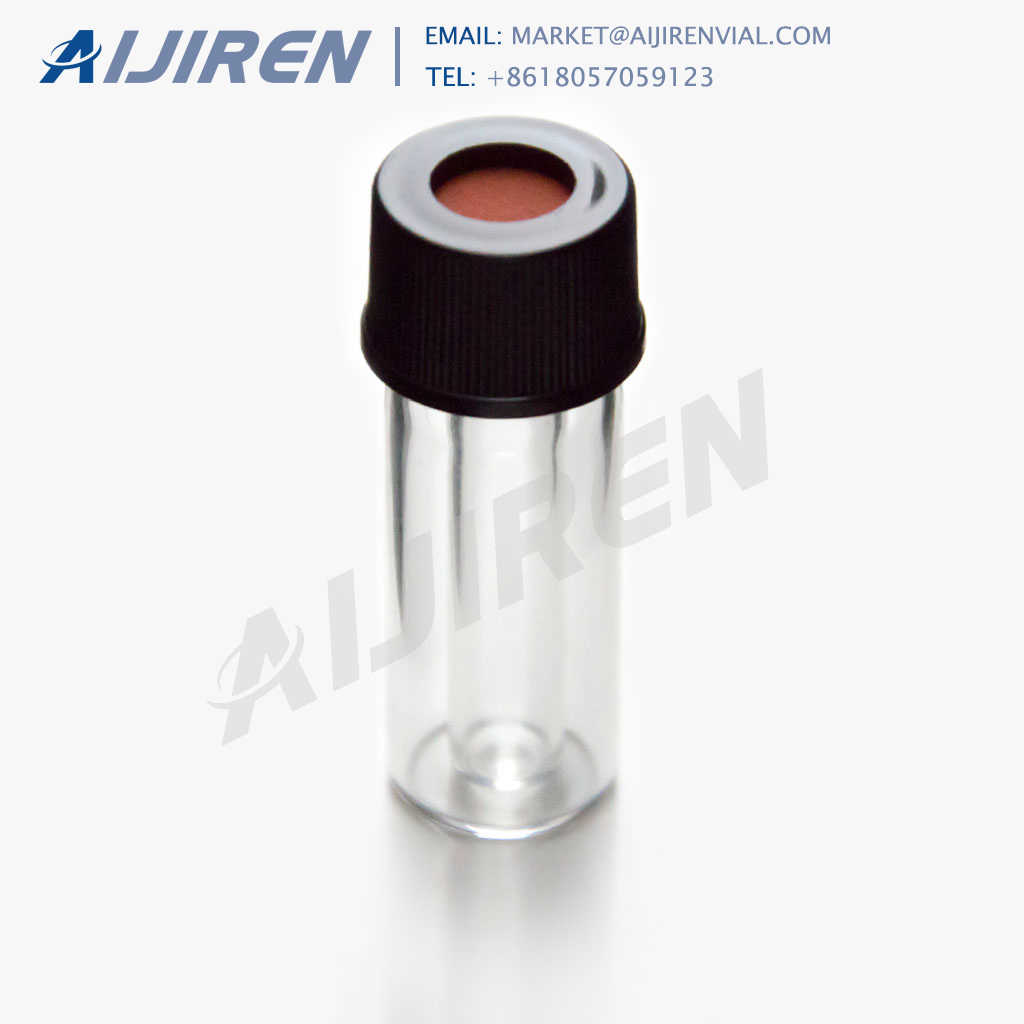

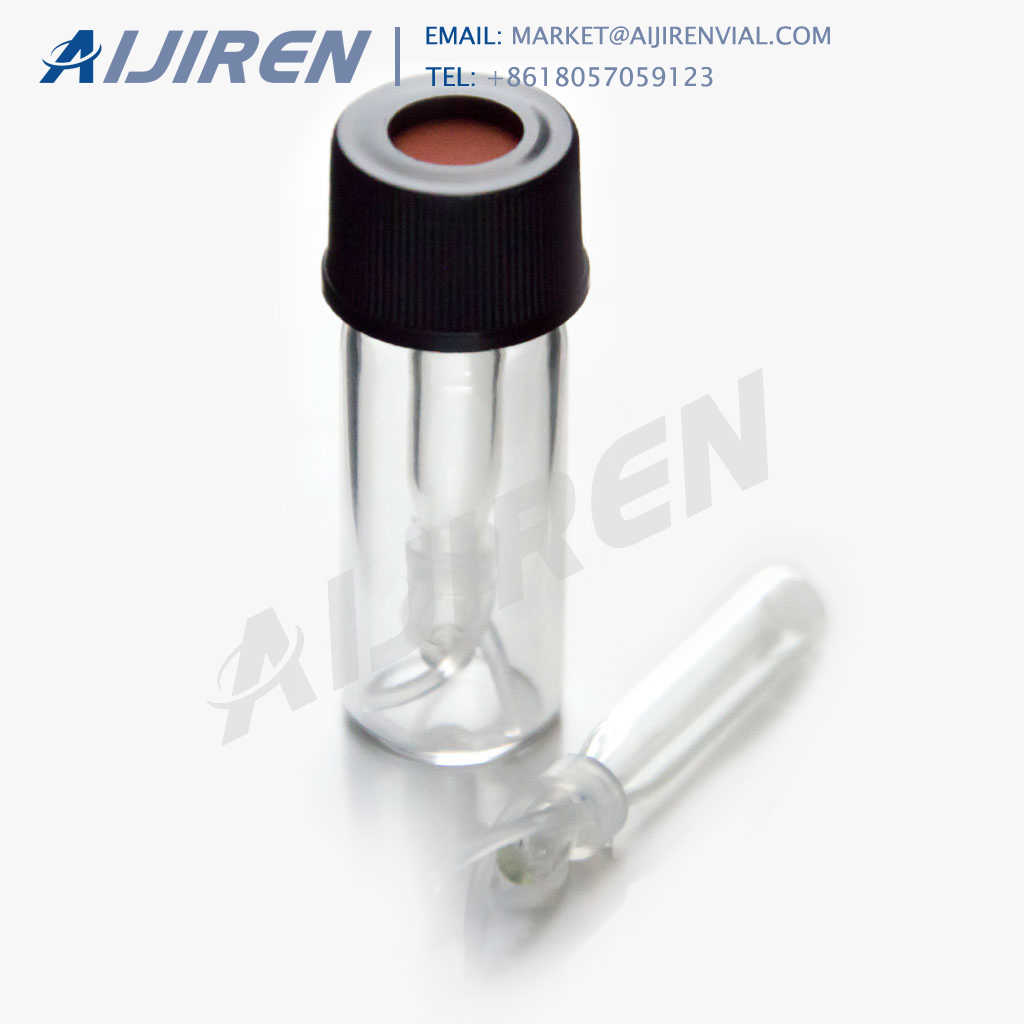

The result is a complete product assembly consisting of molded plastic partially or completely surrounding the insert. Aijiren Tech 250ul insert conical with high quality. There are 3 types of micro-insert, 29*5mm 150uL micro-insert with mandrel interior&polymer feet, 150uL conical bottom micro-insert and 250uL flat bottom micro-insert.

Jan 28, 2021 · Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

Insert molding. The insert molding process conveys the idea that one piece or part is particularly made to be installed inside a larger injection mold, as an interior component or piece. As a result, the original piece or “insert” is transferred to another assembly space for integration with a larger plastic injection molded component.

Many workpieces in modern manufacturing use metal and plastic together. Insert molding is the process of making a plastic mold and inserting another piece, typically metal or other material, into the mold. The result is a custom component with precisely aligned pieces. An insert mold requires specialized equipment and engineered plastic components.

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that,the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products.

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Jun 29, 2019 · In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the mold and what is placed inside the mold. A good example of a part manufactured on an insert molding machine is a Sub D Connector.

how to j 250UL insert molding Design and production guidelines for Insert Molding | Fast Radius Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter.

Sep 13, 2021 · Insert molding vs. Overmolding On the surface, Insert Molding and overmolding seem to be very similar to each other, but there are some subtle differences between them. Contrary to insert molding, overmolding is a two-step process where a plastic component is molded over an already molded part to produce a single component.

Dec 02, 2020 · Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

250ul Plastic Insert with mandrel interior and polymer feet,suits for ND9 Vials 250ul Micro-Insert, clear glass, flat bottom, suits for ND8 Vials 300ul Micro-Insert, clear glass, flat bottom, suits for ND9 Vials 1ml shell vials, 1st hydrol glass, clear, 8mm PE-Plug, soft, without insertion Size 29*5.7mm 31*5mm 31*6mm 8.2*40mm 29*5.7mm 29*5mm

101mm from parting line. Up to 203.2mm if the parting line can pass through the middle of the part. PROJECTED MOLD AREA. 1 3 sq. mm (plastic) 30968 sq. mm (silicone rubber) Height may be limited if using a silicone as the overmold material, and deeper parts are limited to a smaller outline. Minimum part volume is 0.025 cu. in. (40.98 cu. mm).

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal.

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Various types of inserts come with their own benefits and drawbacks, so contact Romeo RIM today for help deciding just which insert is right for your next project! 74000 Van Dyke Ave, Romeo, MI 48065. 586-336-5800 Mon-Fri, 8am until 5pm EST. sales@romeorim.com We reply within 48 hours. Tags: Insert Molding.