Dec 02, 2020 · Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic. Laboratory analytical 250ul spring bottom vial insert for vials

Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. View our design guidelines page for more in-depth details. US. Metric. Maximum Part Size. 18.9 in. x 29.6 in. x 8 in. 480mm x 751.8,, x 203.2mm.

A commonplace use of insert injection molding is creating plastic-covered metal cylinders to bolt pieces together and reduce stress on joined plastic parts. Threaded metal tubes or bracketed mounts minimize the amount of stress borne by the plastic piece. These simple compression limiters are ideally suited for insert injection molding since

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Dec 13, 2019 · There are three main techniques for encapsulating an insert: Multi-component injection molding, also known as co-molding, involves injecting some combination of multiple plastics and metals into the mold at the same time. These materials then join together, resulting in a stiffer, stronger piece. Multi-shot injection molding is similar to multi

For more, read our Injection Molding Guide: https://www.jayconsystems.com/tutorials/cat/tutorials/post/engineering-guidelines-to-designing-plastic-parts-for

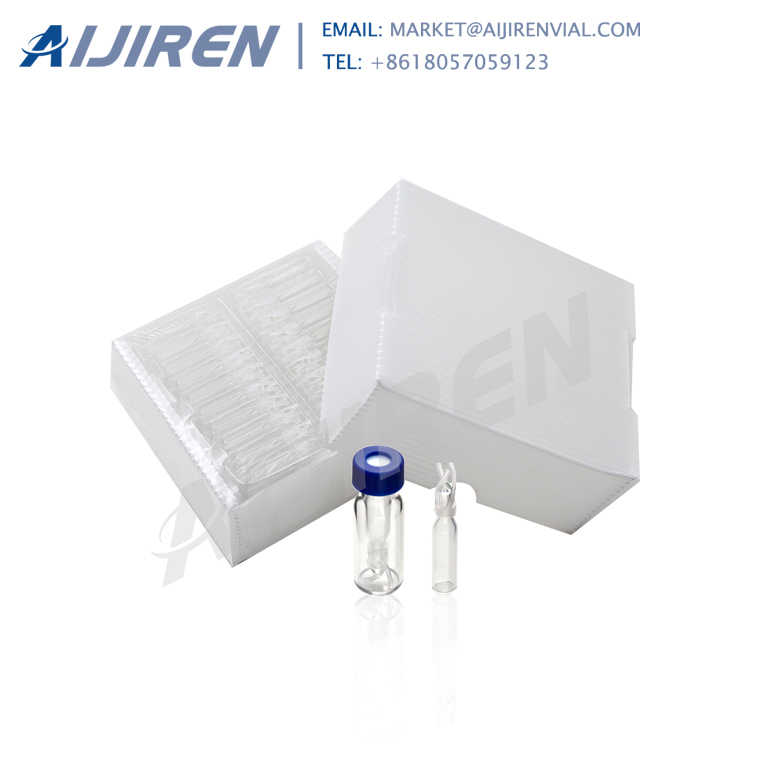

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that,the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products. Sigma 250ul micro insert vial

Aug 15, 2019 · Typically insert molding, or overmolding, requires accurately placing part(s) made from metal or other suitable materials (referred to as the insert) into the mold, closing the mold and then injecting the plastic into and/or around the insert(s). A typical application would be electrical connectors that incorporate machined metallic pins or sockets into a molded plastic housing. Most insert

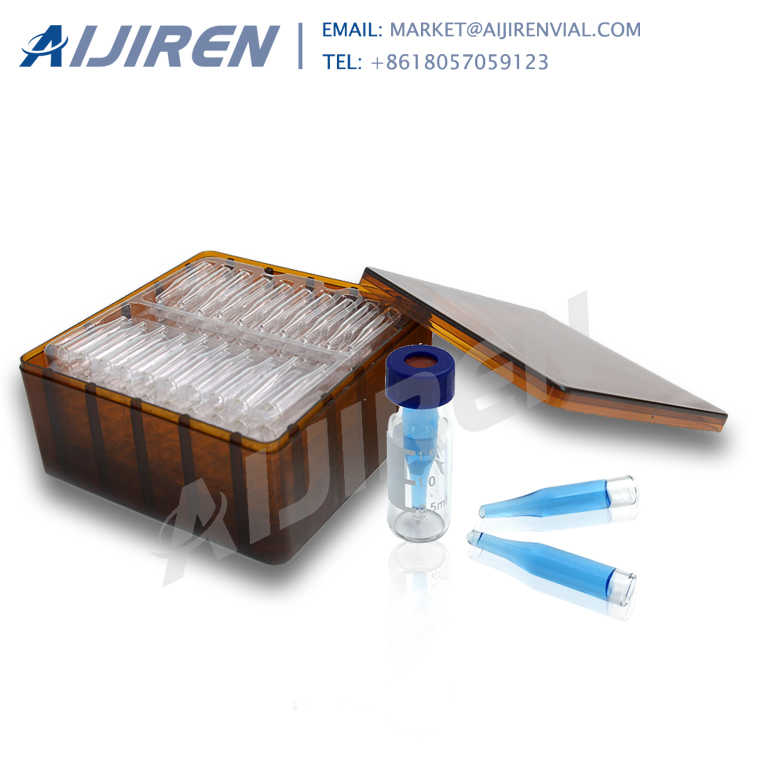

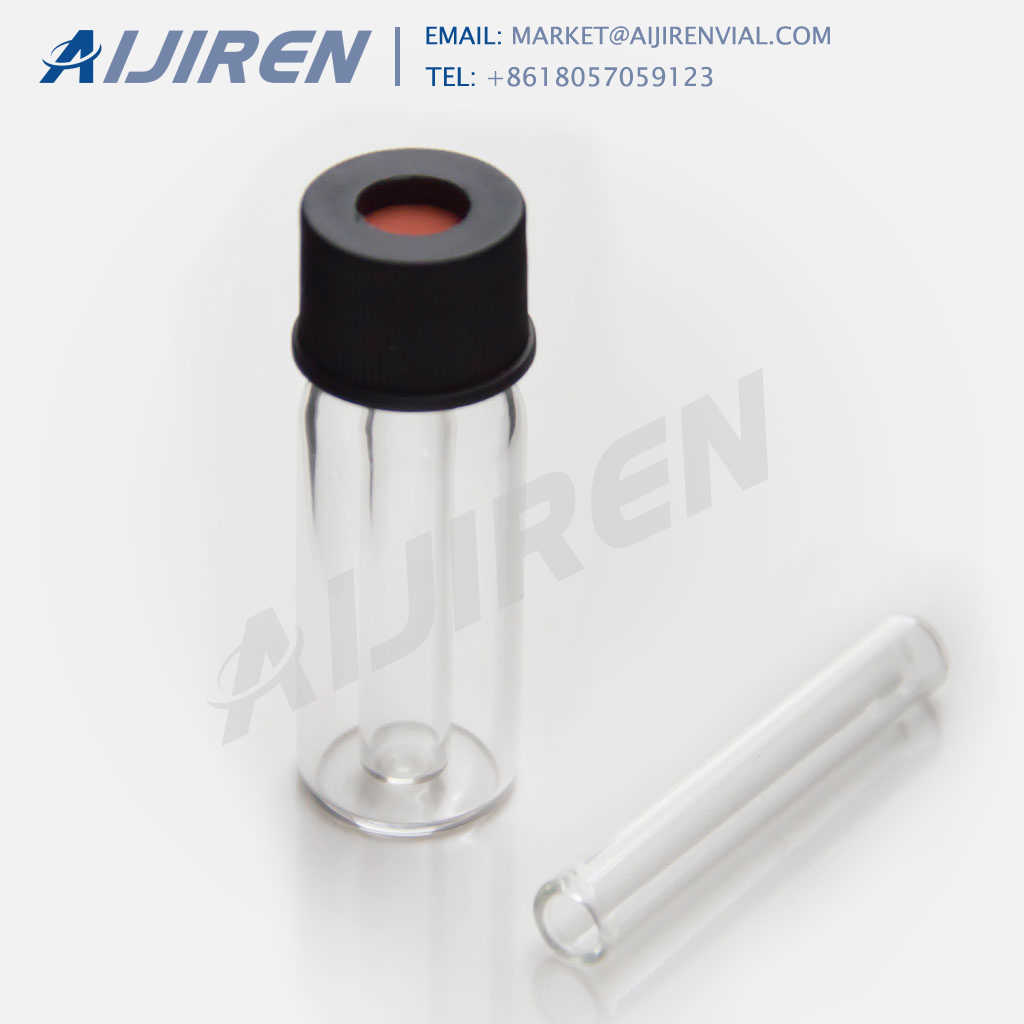

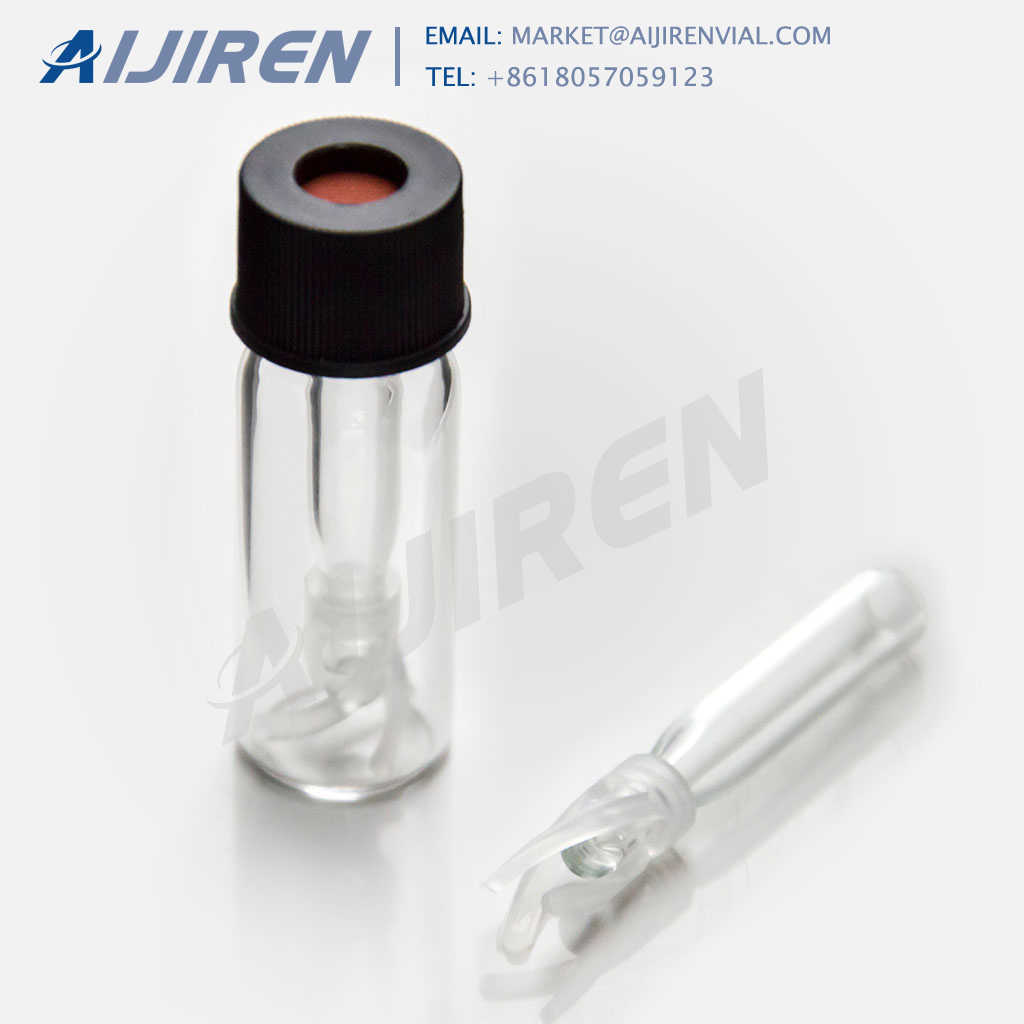

250ul micro insert for wholesales-HPLC Vial Inserts Micro-Inserts--Aijiren HPLC Vials. 250uL Micro-Insert with Mandrel Interior, & Polymer Feet, 29*5.7mm, Suits for 10-425 Vials 4. 11mm Snap Ring Vials Micro-Inserts Part No. I300 IV250-I(Economy) IV250 IP250-I(Economy) IP250 Description 300uL Micro-Insert . 250ul Vial Insert With Poly Spring

High-Quality Insert Molding. LLS Health’s experienced team specializes in a variety of insert molding process techniques to deliver the highest-quality product possible. Our expertise includes: High bond strength. Experience with restricted, unrestricted and compounded materials. Numerous shapes and sizes. Extruded components to molded

. Manufacturer: Aijiren Technologies. Description. Aijiren Vial insert, 300 uL, polypropylene, polymer feet. Do not fill to more than 250 uL, 100/pk Insert size: 5.6 x 30 mm - High Recovery Vials & Inserts. UNSPSC Code . - 58. Specifications.

All conical styles of inserts are offered with the traditional pulled point as well as the improved mandrel point. Pulled point inserts are more economical, but mandrel point inserts provide a more pointed and uniform tip that enables better sample recovery. Micro-Inserts can be used on all 1.5ml vials. Effectively relieves the pressure of syringe.

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal. Micro Inserts Details