OVERVIEW. Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.

Dec 02, 2020 · Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Dec 02, 2020 · The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic.

Our international team of engineers work with you to make your product ideas a reality through manufacturing technologies like metal 3D printing, vacuum casting, CNC machining, plastic injection molding and a range of finishing services.

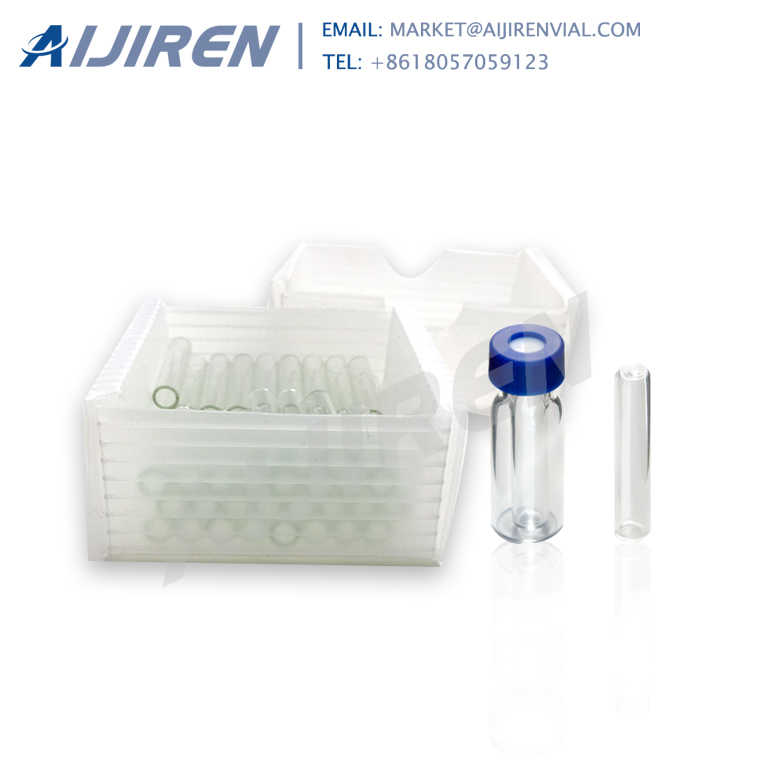

5190-4073 | AijirenPart Number:5190-4073. 250ul insert, polypropylene w/grad 100pk. Add to Favorites. + Create New list. Item successfully added to your list. List Price: $35.75 /

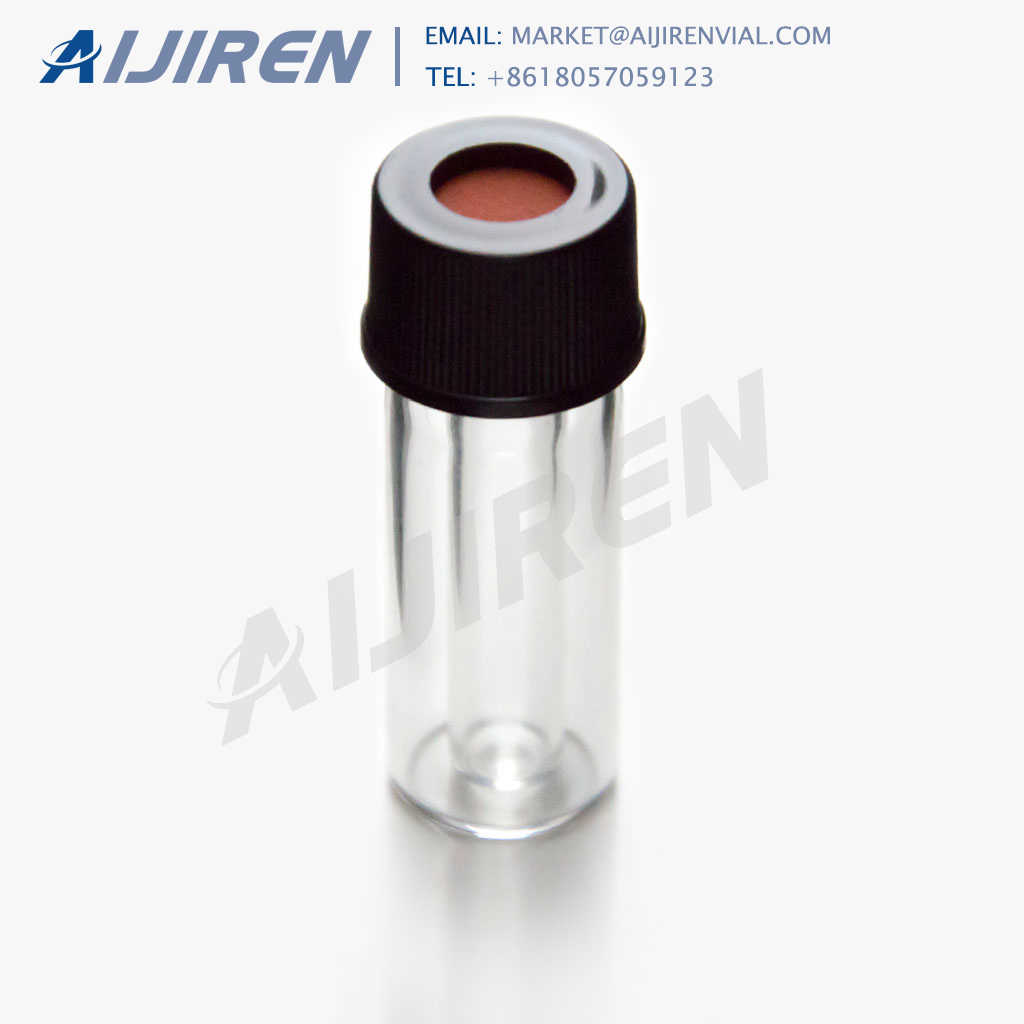

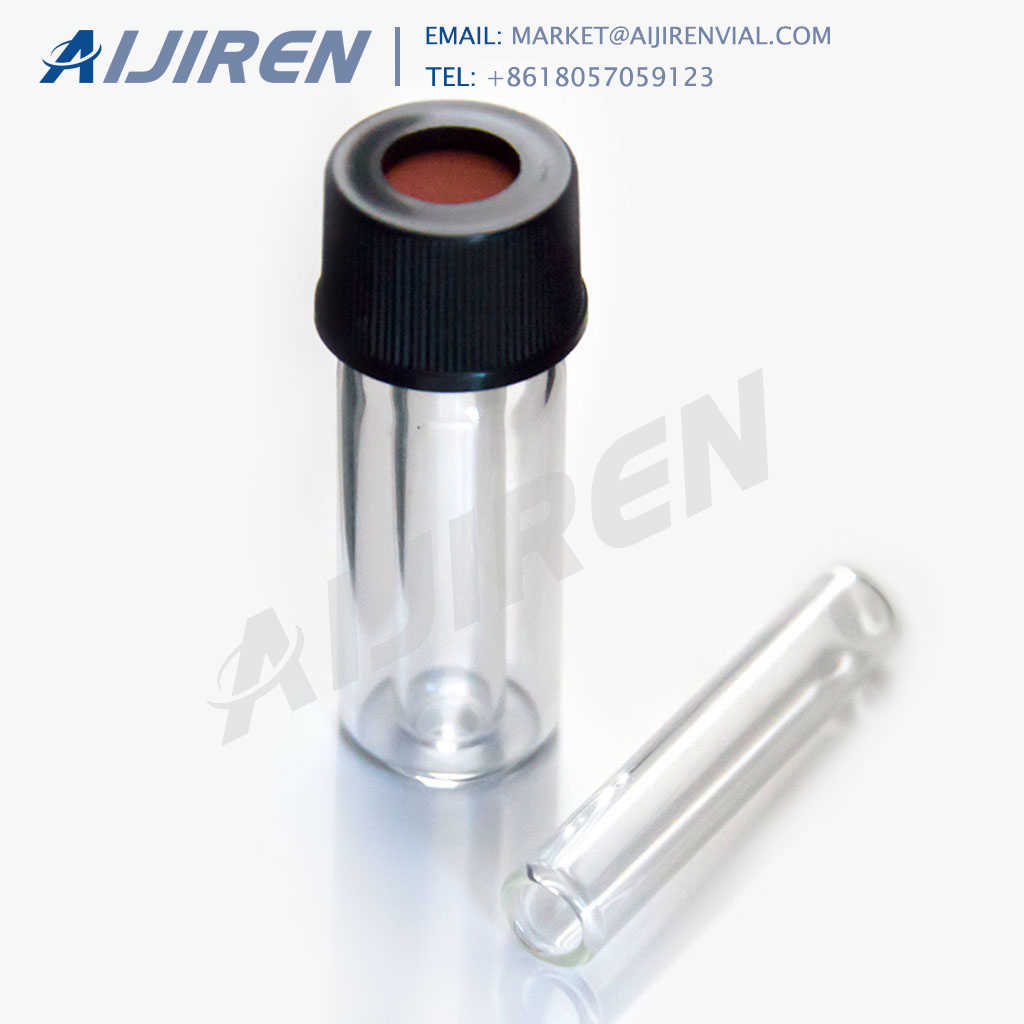

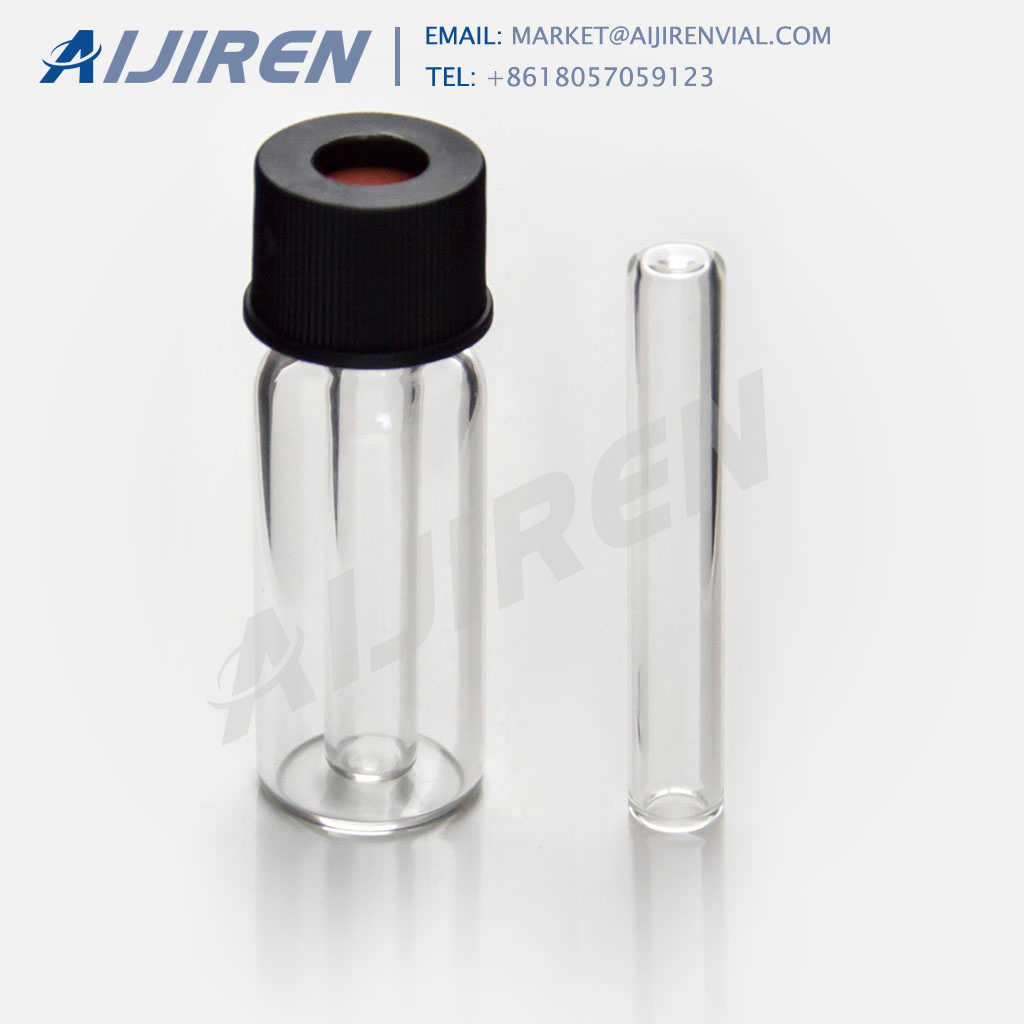

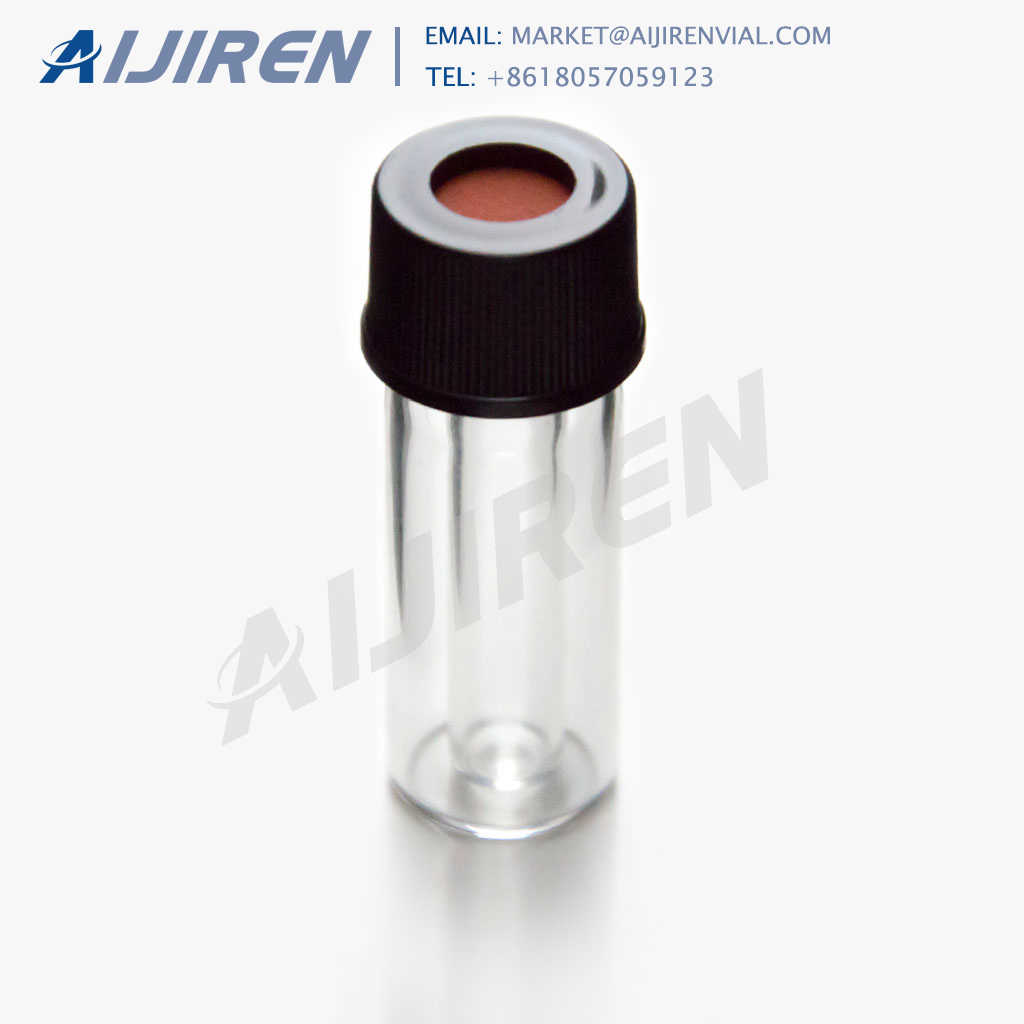

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

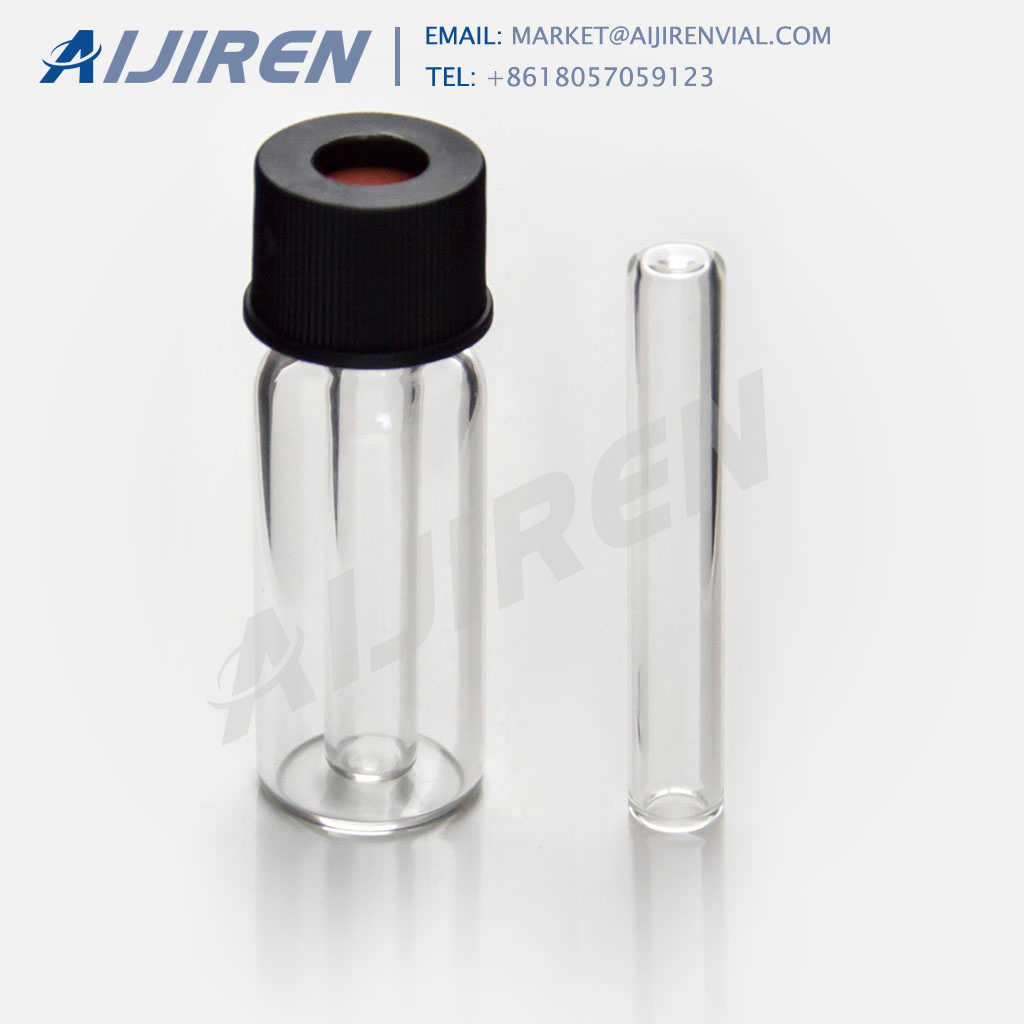

. Manufacturer: Aijiren Technologies. Description. Aijiren Vial insert, 300 uL, polypropylene, polymer feet. Do not fill to more than 250 uL, 100/pk Insert size: 5.6 x 30 mm - High Recovery Vials & Inserts. UNSPSC Code . - 58. Specifications.

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

For more, read our Injection Molding Guide: https://www.jayconsystems.com/tutorials/cat/tutorials/post/engineering-guidelines-to-designing-plastic-parts-for

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Insert molding combines traditional molding processes, and introduces extra objects to form parts that require specific spaces or additional materials. One example might be a piece with several hose attachments or a container that has angled funnel points. In these cases, rods are inserted during molding, and then removed when cooled to produce

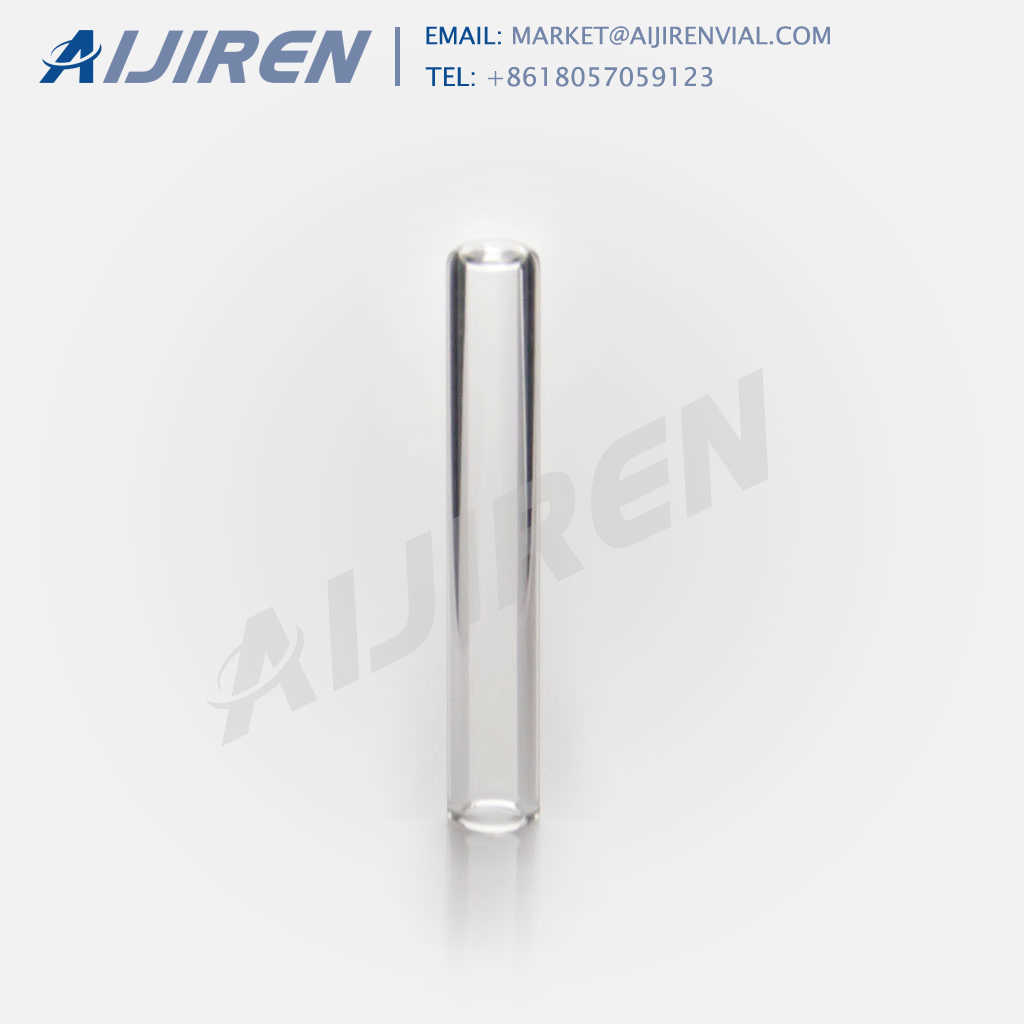

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal.

Insert Molding. Insert injection molding involves encapsulating a previously fabricated component in molten resin to produce a finished part. The inserted component is usually a simple object, such as a knife blade or surgical tube, but in some cases, inserts can be as complex as a battery or motor. Plastic insert molding is ideal for improving

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.