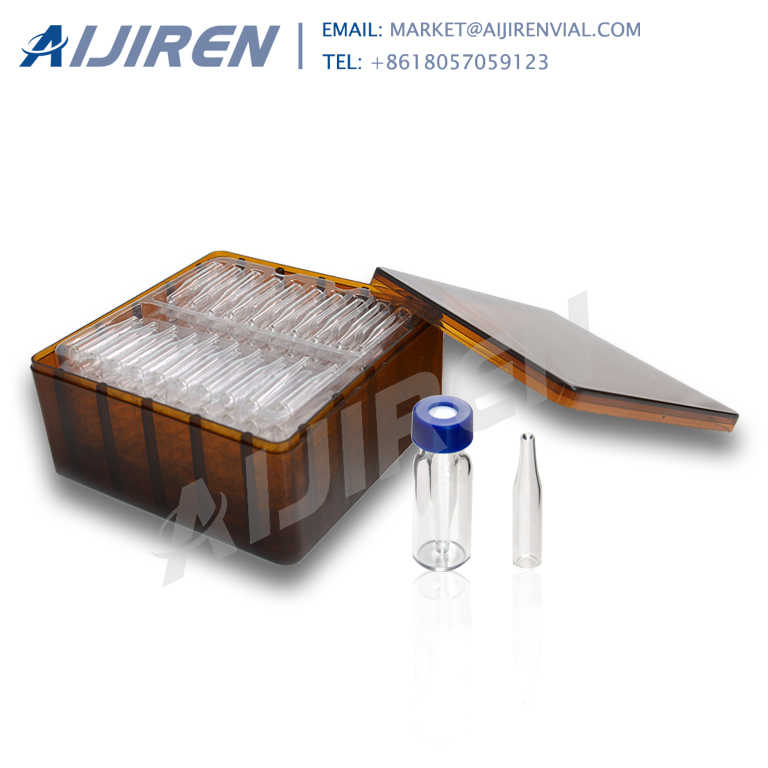

5190-4073 | AijirenPart Number:5190-4073. 250ul insert, polypropylene w/grad 100pk. Add to Favorites. + Create New list. Item successfully added to your list. List Price: $35.75 /

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

Jun 29, 2019 · In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the mold and what is placed inside the mold. A good example of a part manufactured on an insert molding machine is a Sub D Connector.

Insert Molding. Insert injection molding involves encapsulating a previously fabricated component in molten resin to produce a finished part. The inserted component is usually a simple object, such as a knife blade or surgical tube, but in some cases, inserts can be as complex as a battery or motor. Plastic insert molding is ideal for improving

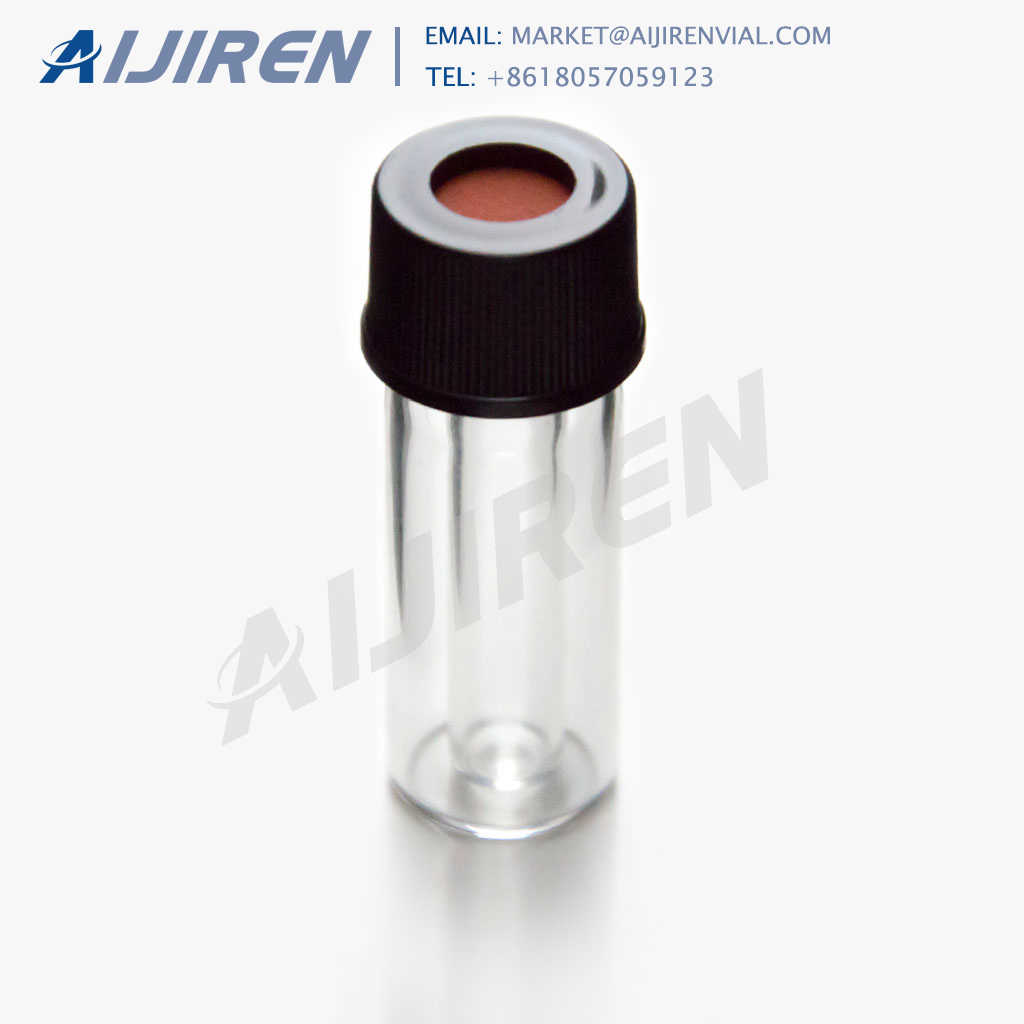

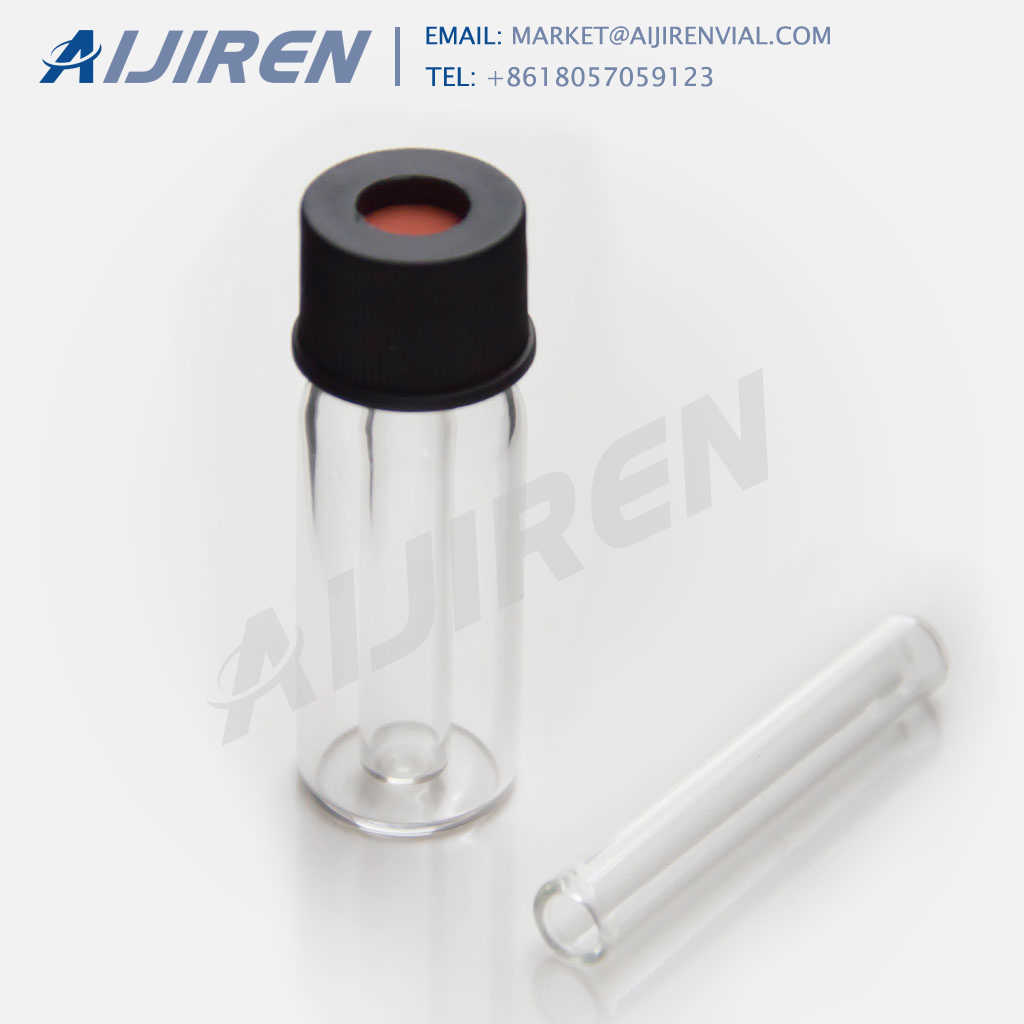

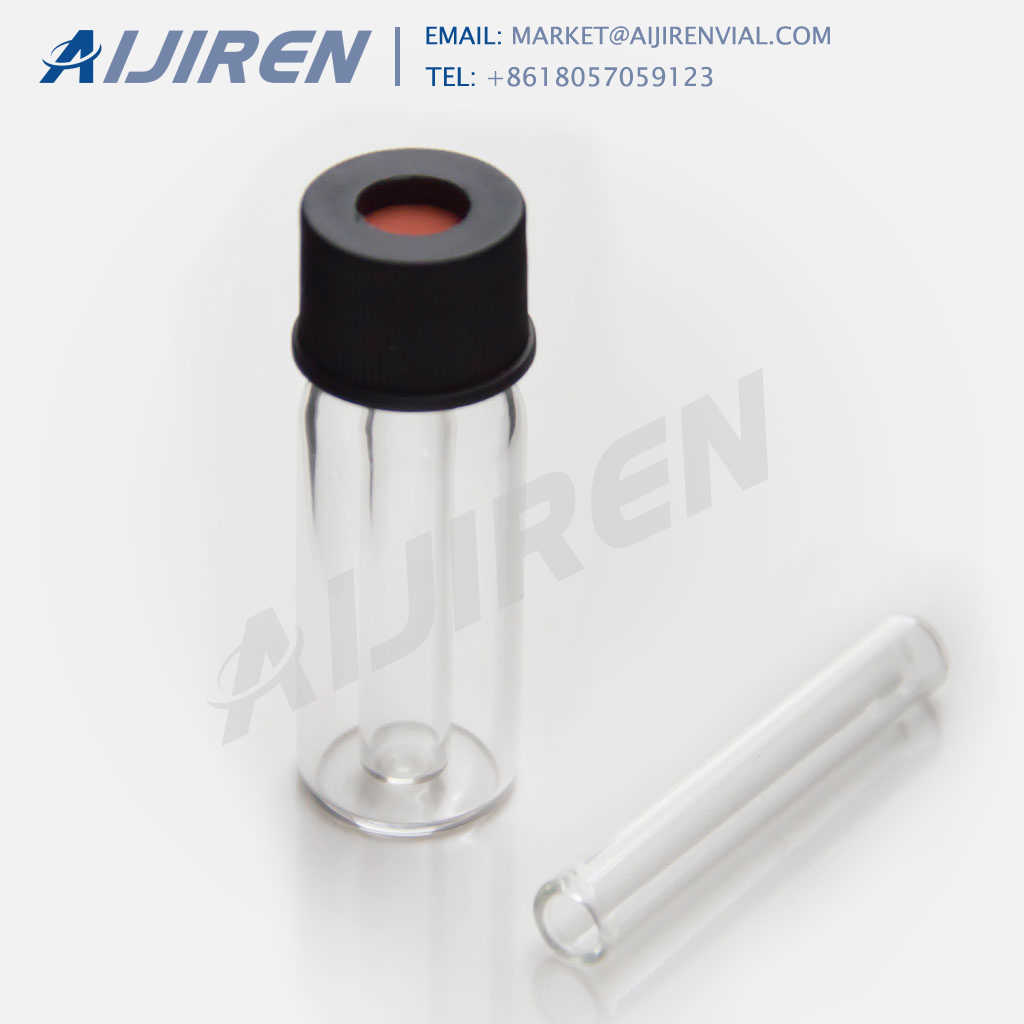

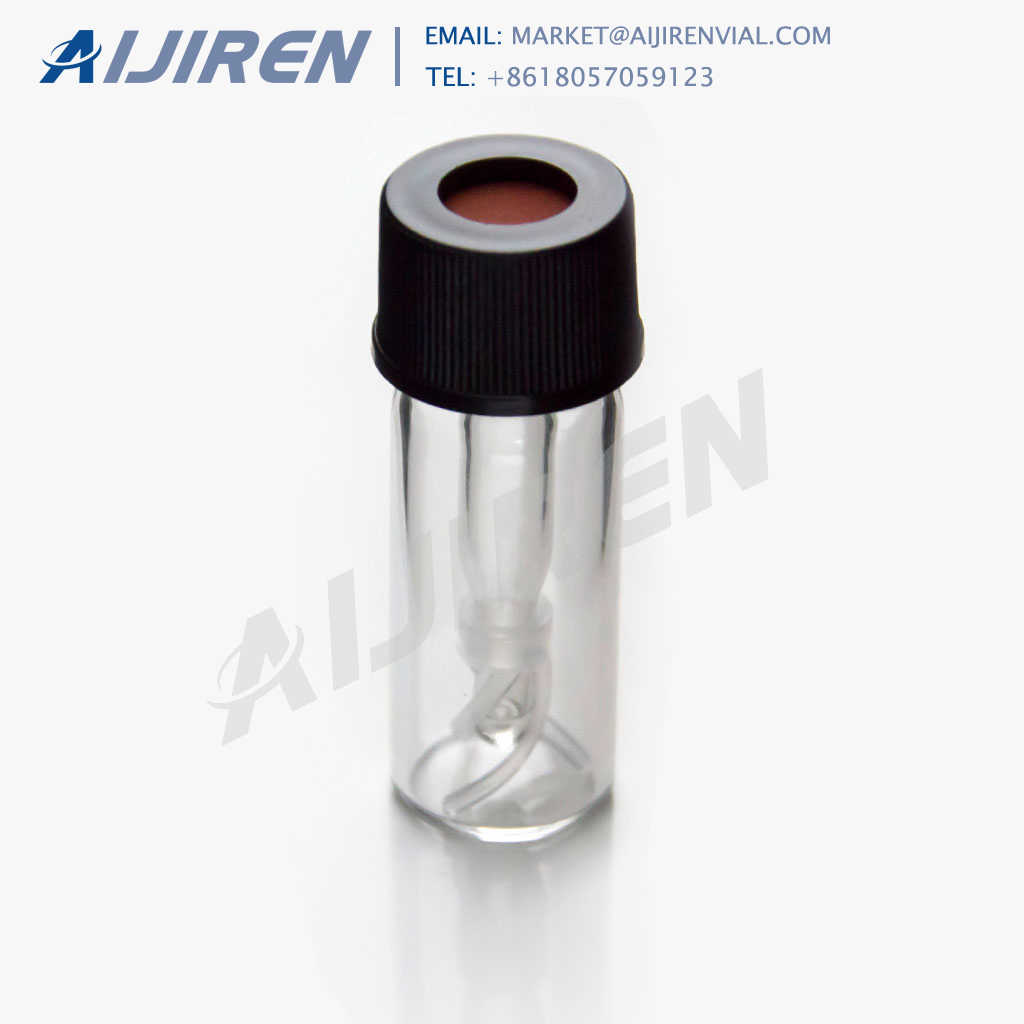

The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic. Laboratory analytical 250ul spring bottom vial insert for vials

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Our international team of engineers work with you to make your product ideas a reality through manufacturing technologies like metal 3D printing, vacuum casting, CNC machining, plastic injection molding and a range of finishing services.

Insert molding. The insert molding process conveys the idea that one piece or part is particularly made to be installed inside a larger injection mold, as an interior component or piece. As a result, the original piece or “insert” is transferred to another assembly space for integration with a larger plastic injection molded component.

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that,the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products. Sigma 250ul micro insert vial

Dec 02, 2020 · Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

OVERVIEW. Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.

For more, read our Injection Molding Guide: https://www.jayconsystems.com/tutorials/cat/tutorials/post/engineering-guidelines-to-designing-plastic-parts-for

Feb 23, 2022 · Put the insert mold or part into the plastic injection molding cavity. Support the insert piece to avoid it from falling off during the insert molding process. The plastic resin should be poured into the plastic injection molding cavity. Allow the resin to form around the insert piece. After this, you are done.

A commonplace use of insert injection molding is creating plastic-covered metal cylinders to bolt pieces together and reduce stress on joined plastic parts. Threaded metal tubes or bracketed mounts minimize the amount of stress borne by the plastic piece. These simple compression limiters are ideally suited for insert injection molding since