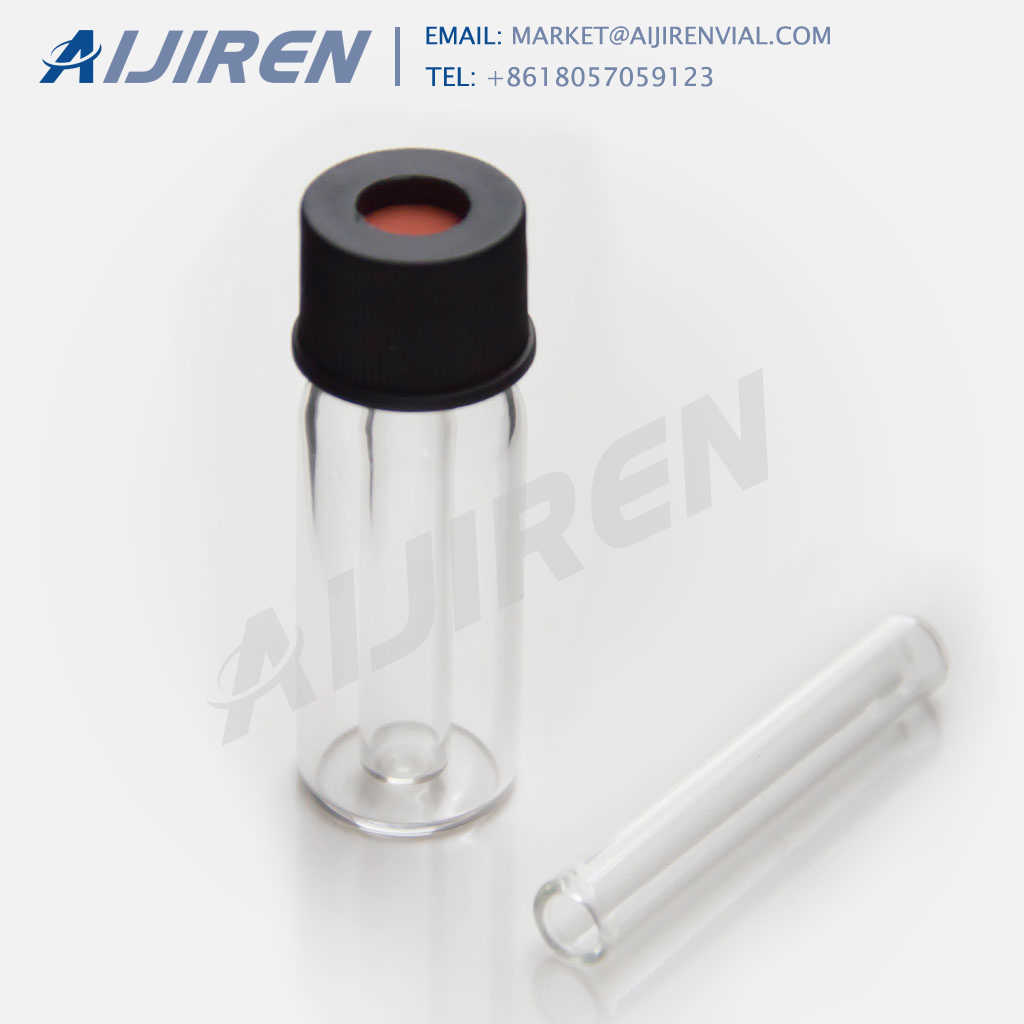

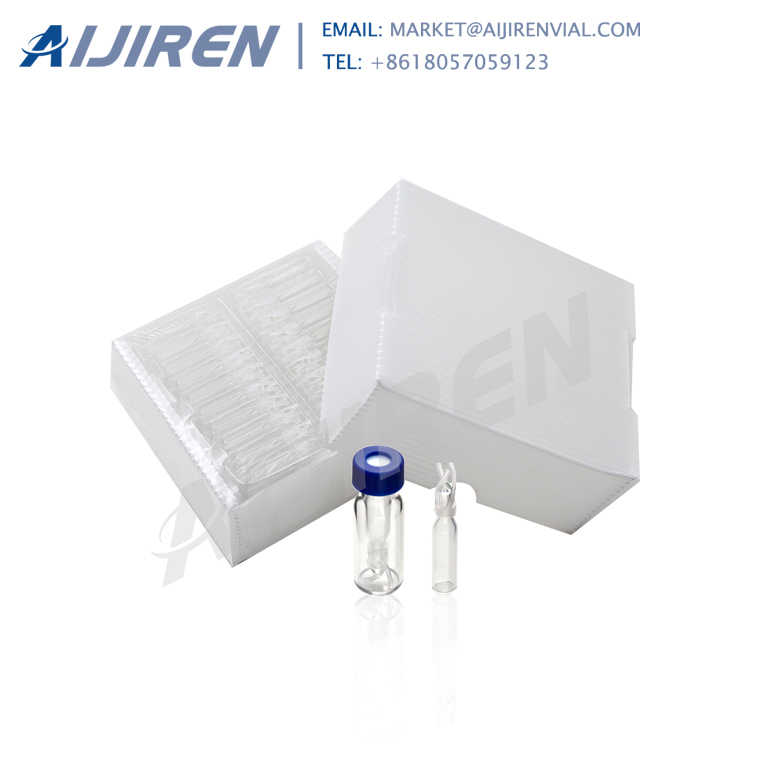

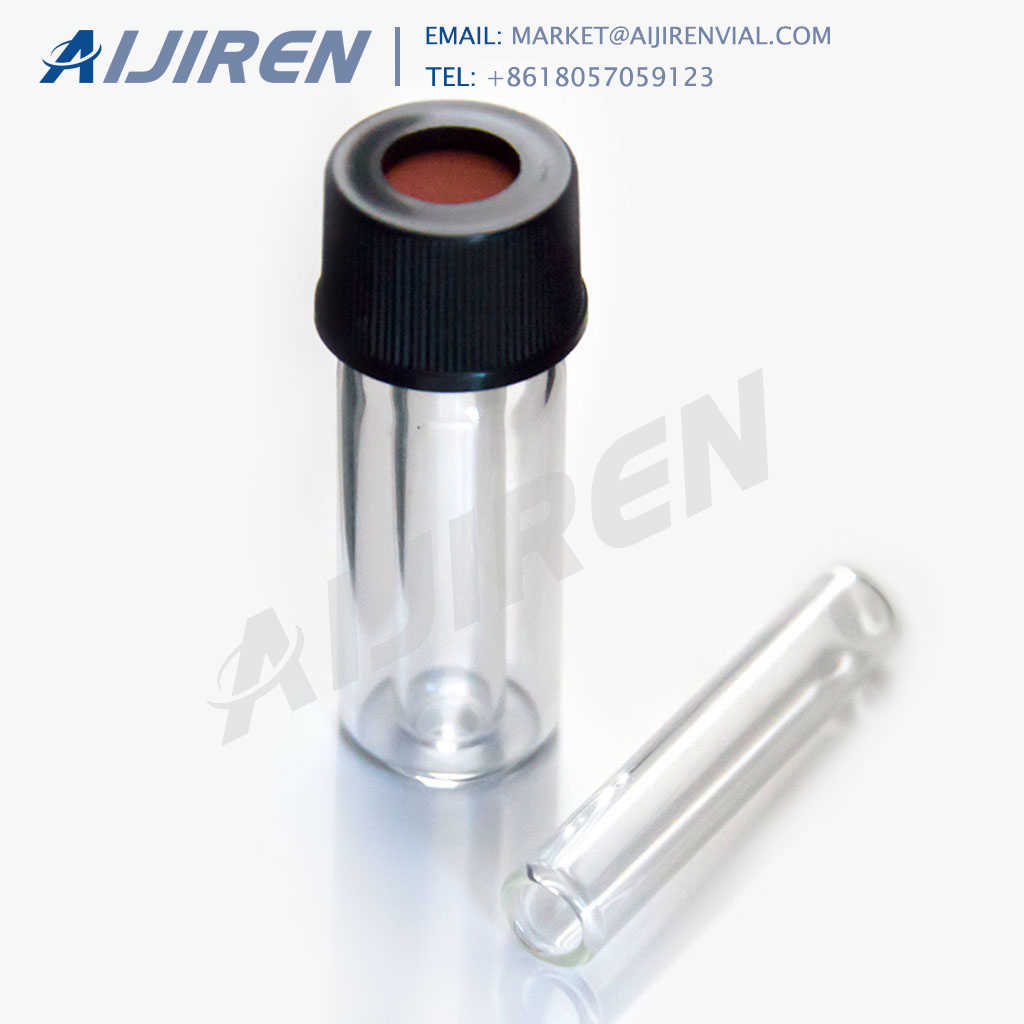

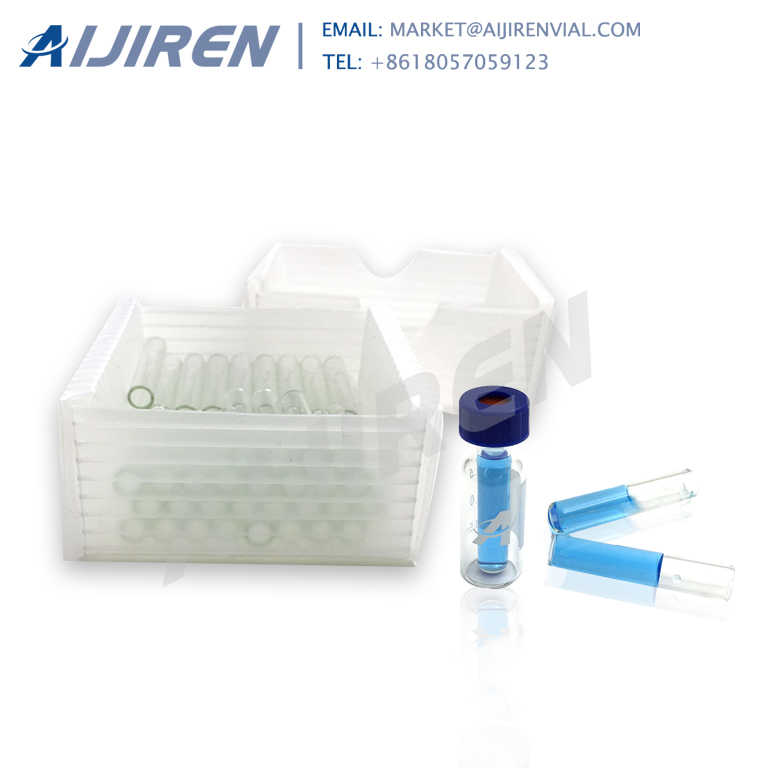

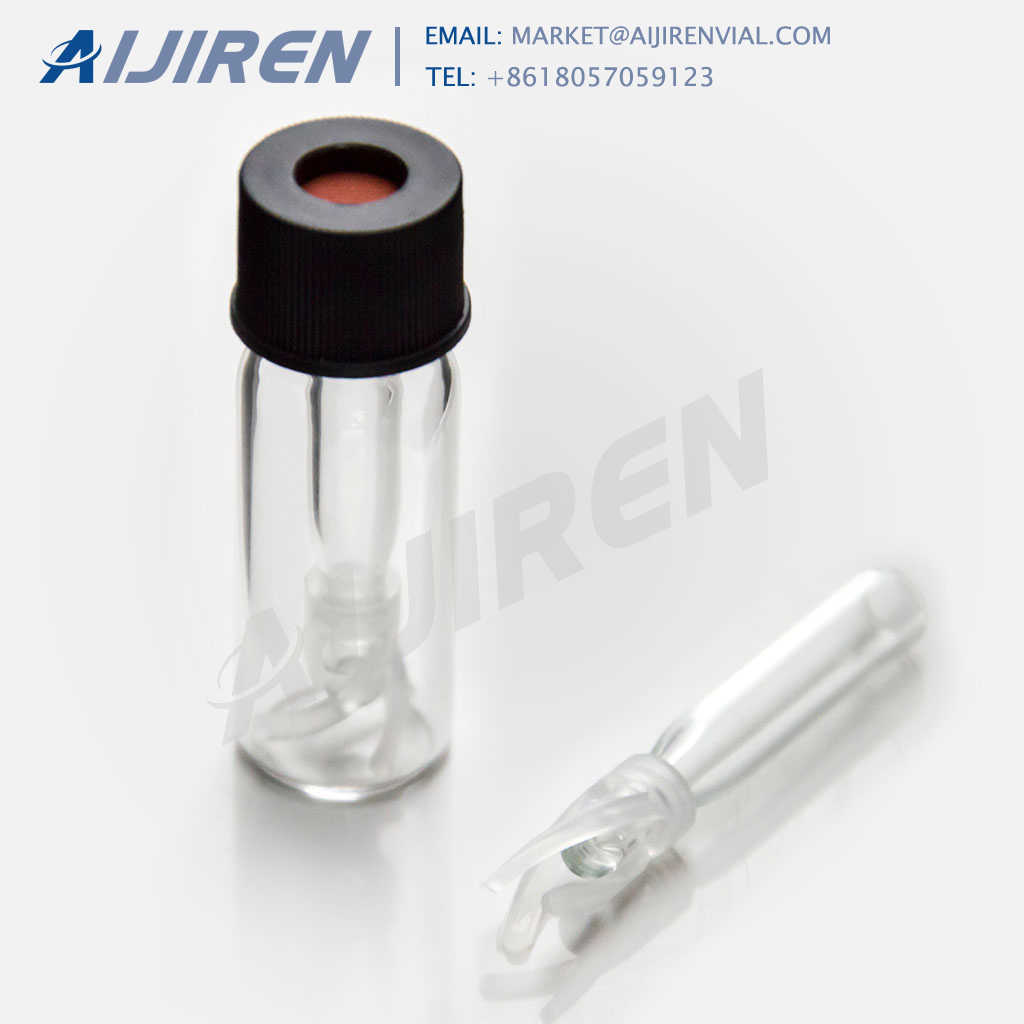

Athena Vial Micro-Insert, Size: 250ul, Rs 800 /pack Athena. Vial Inserts Micro-Insert 0.3mL Amber Screw Vial Integrated w/Micro-Insert, w/Write-on Spot,Base Bonded, 11.6*32mm 1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A

Clear Glass Micro Insert is used to ensure the most accurate and reliable analysis of your lab samples. 250ul Micro-Inserts, flat Bottom. Micro inserts, when used in conjunction with autosampler vials, allow for maximum sample recovery and easier sample removal. Micro Inserts Details

Insert molding vs overmolding. Overmolding is a process by which two or more different materials are used to create a single product. Overmolding allows manufacturers to create pieces that combine the strengths of different plastics. One common example would be a simple toothbrush, featuring a hard plastic core and a soft, rubber-like grip.

Dec 02, 2020 · Insert Molding Steps. The first step in insert molding is to custom-build a tool to accept a solid component or part as an insert. That insert is placed into the tool, and a thermoplastic elastomer (TPE) is injected into the tool cavity, coating the insert in a smooth layer of plastic. After cooling, the tool is opened and the part is removed

All conical styles of inserts are offered with the traditional pulled point as well as the improved mandrel point. Pulled point inserts are more economical, but mandrel point inserts provide a more pointed and uniform tip that enables better sample recovery. Micro-Inserts can be used on all 1.5ml vials. Effectively relieves the pressure of syringe.

Aug 21, 2019 · Insert molding is a process that starts with placing metal, ceramic, or plastic parts into the plastic injection mold. After those parts have been properly placed, the mold is filled with molten plastic in the regular injection molding process. Once the plastic has cooled, the inserted parts are now firmly bound to, and integrated into, the

Insert molding is a molding process in which plastic is injected after a prepared different material, and the insert is loaded into the mold. Besides that,the fused plastic is perfectly joined and cured together with the insert. The insert molding process can be used for the production of integrated products.

The following is a quick review of these steps. Preparing the Machinery: Preparing the machinery used in the process is the first step when it comes to designing insert molding. One has to check the machine tolerances and the alignment of every part to ensure that the final product comes out clean. Inserts: The next step is deciding the type of

Insert molding is an injection molding process used to encapsulate a component in a plastic part. The process consists of two basic steps: First, the component is loaded into the mold before the molding process. Second, as molten plastic is injected into the mold, it takes the shape of the part and locks the component into the plastic.

For more, read our Injection Molding Guide: https://www.jayconsystems.com/tutorials/cat/tutorials/post/engineering-guidelines-to-designing-plastic-parts-for

Jun 29, 2019 · In the simplest sense, insert molding is done on an injection molding where you mold plastic around an object that has been placed in a mold. The final product is determined by the shape of the mold and what is placed inside the mold. A good example of a part manufactured on an insert molding machine is a Sub D Connector.

Insert injection molding involves encapsulating a previously fabricated component in molten resin to produce a finished part. The inserted component is usually a simple object, such as a knife blade or surgical tube, but in some cases, inserts can be as complex as a battery or motor. Plastic insert molding is ideal for improving the strength

Insert Molding is an injection molding process that works especially well for parts that have threaded holes. It can also help you create better wheels, pulleys, fan blades, and other similar parts. Done correctly, insert molding can help: Eliminate assembly: You can make parts all at once instead of having to do assembly after the fact.

Mar 06, 2021 · The mold inserts or insert molding is actually a very beneficial technique of injection molding in which molders insert the metal part into the mold prior to the factual injection molding. Moreover, insert molding involves encapsulating a product in molded plastic. Basically, it is quite a faster process as you can mold the two plastic materials at the same time. The insert is precisely positioned inside the mold either manually or by a robotic arm. The mold then closes and plastic is molded

Apr 28, 2021 · The insert molding process typically involves the incorporation of another material into a plastic component. This incorporation is to provide a localized hard point for locating or fastening components. Inserts are usually for providing a wear-resistant area for moving components. One of the most common forms of insert molding is the