how to f 250UL insert molding

Design and production guidelines for Insert Molding | Fast Radius

Generally speaking, the insert should extend a minimum of 0.016” (0.4 mm into the cavity of the mold), and, in order to prevent sink marks in the plastic, the molding beneath the insert should be a minimum of one-sixth the insert’s diameter. A good rule of thumb when designing inserts is to ensure that they stay small relative to the

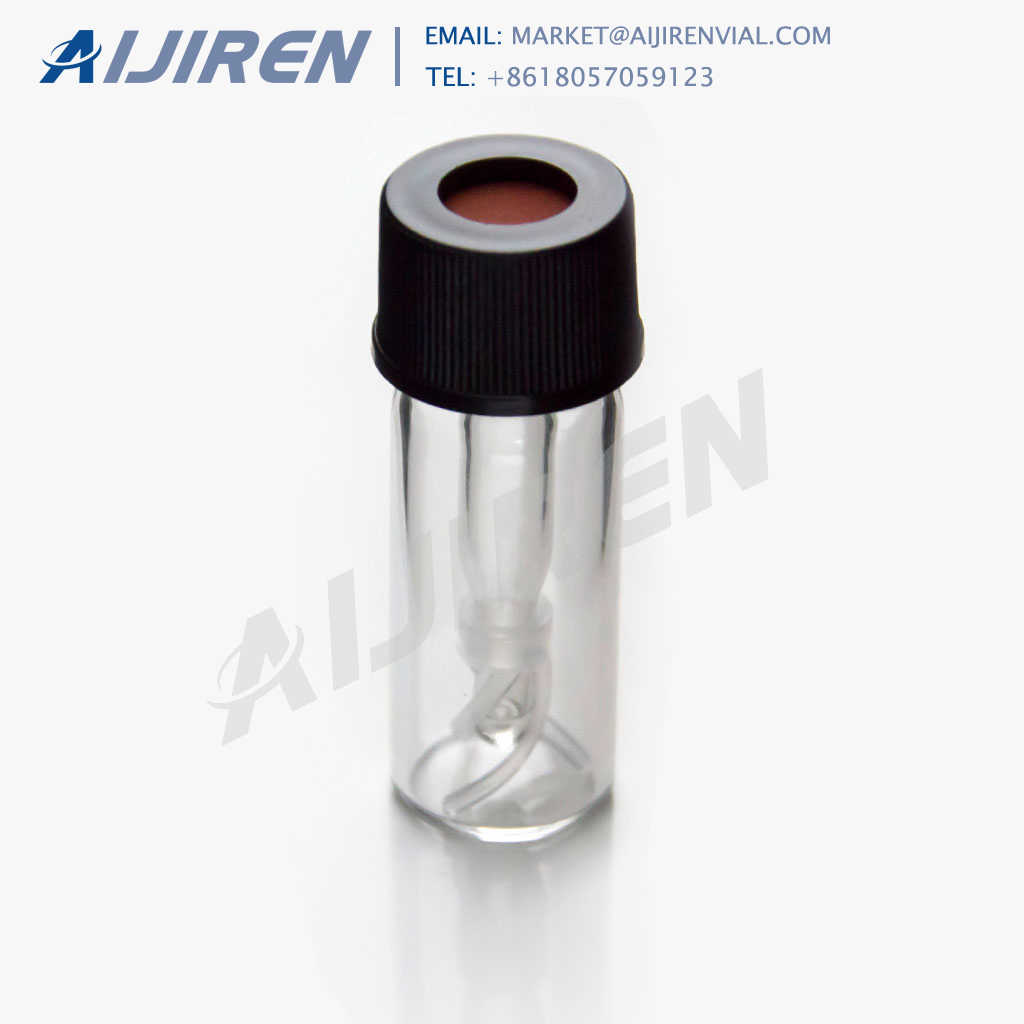

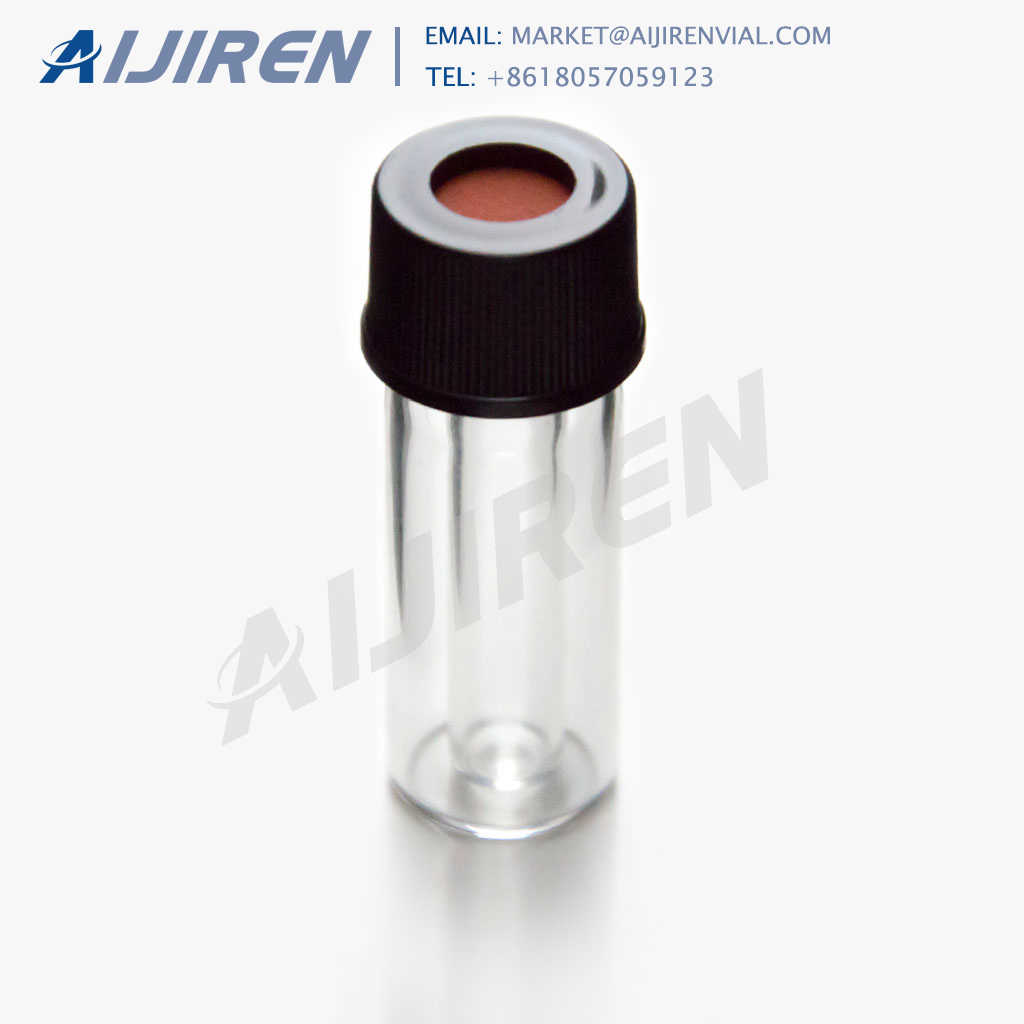

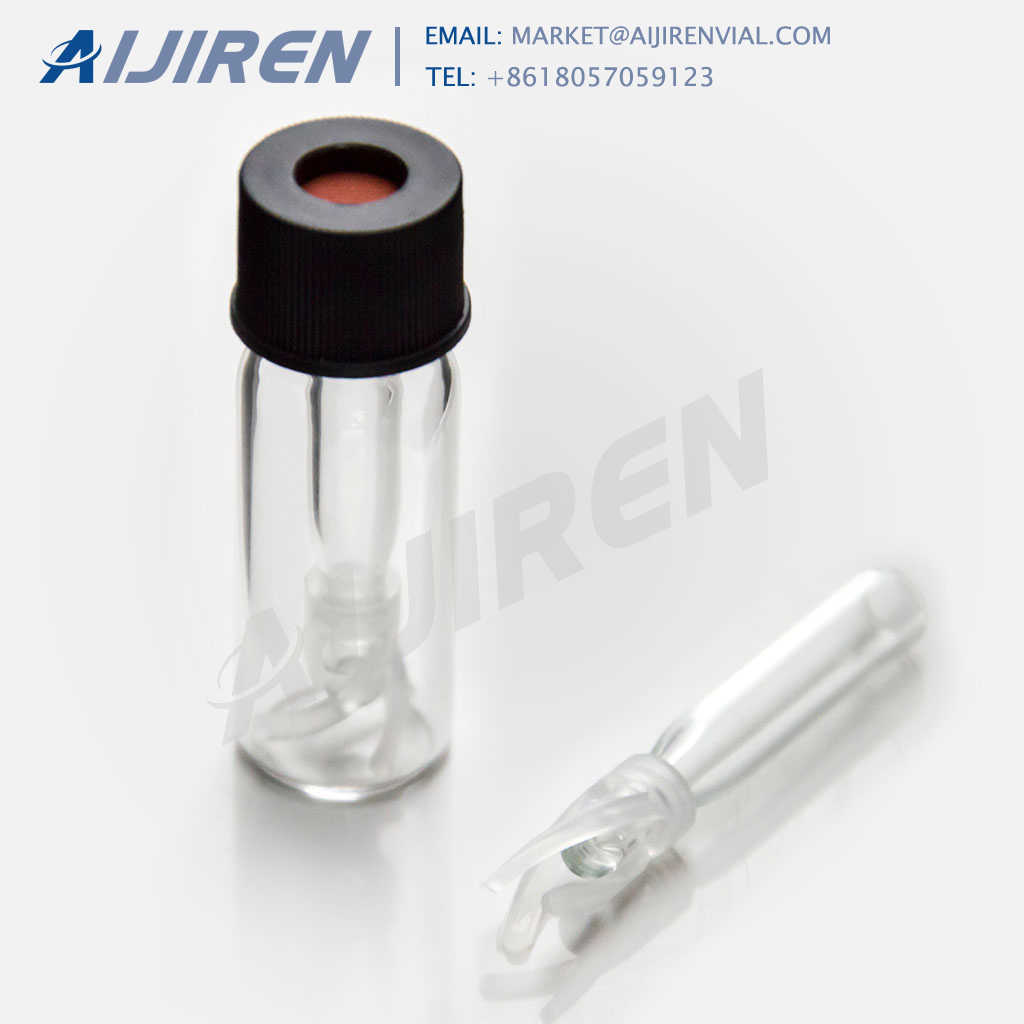

how to v 250UL insert molding-HPLC Vial Inserts

Sigma 250ul insert with mandrel interior and ...

MORE